Interfacial and CEAD Announce Strategic Partnership to Advance Large-Scale Additive Manufacturing Materials

BY Composights

Published: 02 Jul 2025

Interfacial,

a Nagase Group company known for its advanced

materials innovation, has announced a strategic partnership with CEAD, a pioneer in large-scale additive

manufacturing (LFAM) technology. The collaboration represents a significant

milestone in Interfacial’s mission to deliver integrated, application-driven material solutions for LFAM and other

industrial markets.

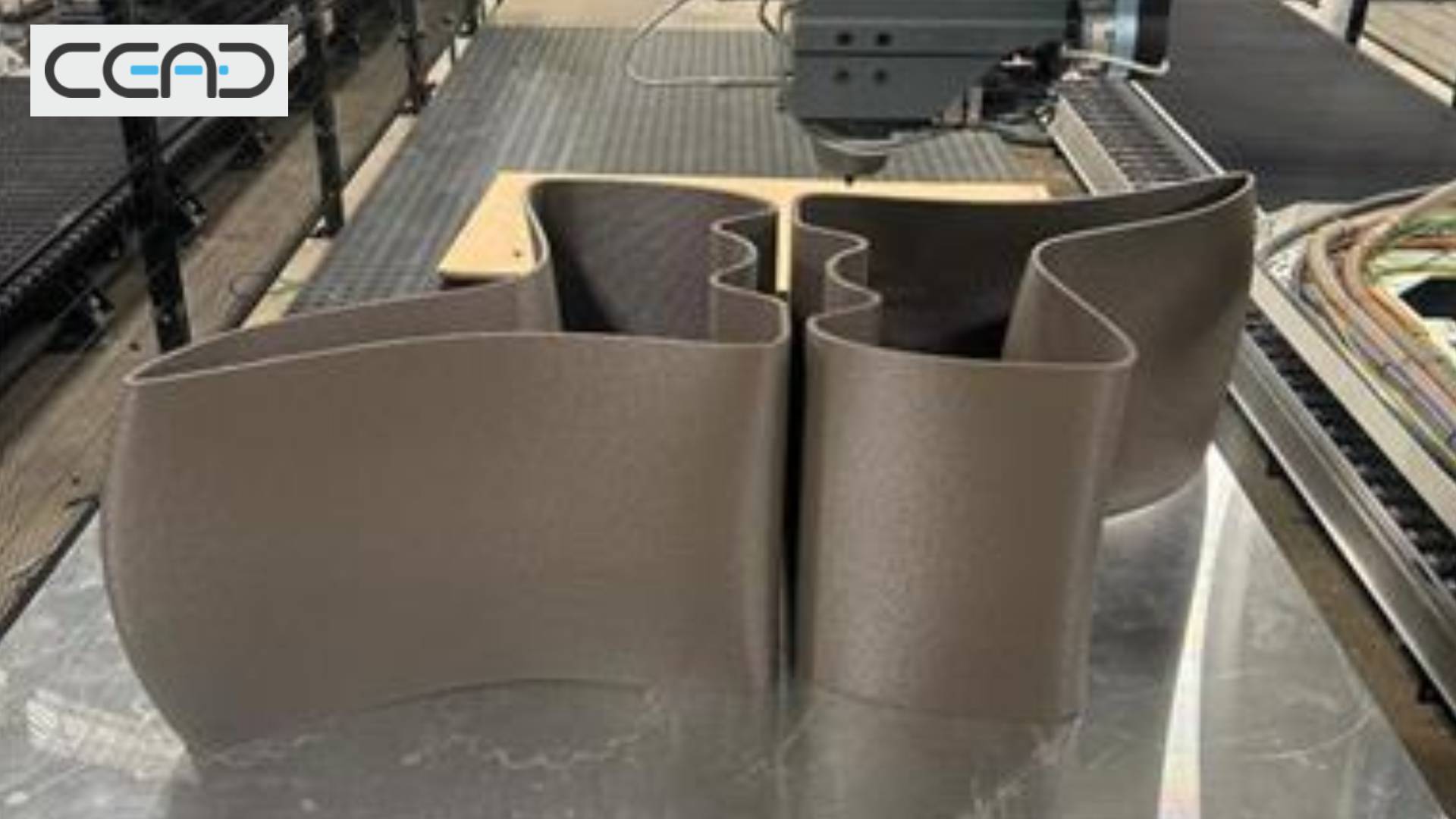

Under this partnership, Interfacial becomes a CEAD material tier

supplier, gaining strategic access to a CEAD

Flexbot system installed locally at Stack3D,

a leading provider of turnkey 3D

printing services. This setup will enable Interfacial to rapidly evaluate,

validate, and refine custom thermoplastic

materials and functional composites

for a broad range of LFAM applications,

including architectural facades, interior design, canopy structures, retail and

hospitality environments, marine and motorsports components, and industrial

tooling.

“Collaborating with CEAD allows us to close the gap between

formulation and production-ready solutions,” said JP Masson, Vice President of Sales at Interfacial. “Together, we

can deliver faster development, better performance, and broader adoption of

LFAM technology.”

By combining Interfacial’s expertise in functional compounds and scalable

manufacturing platforms with CEAD’s robotic 3D printing and CNC milling

capabilities, the partnership creates a comprehensive ecosystem for

developing LFAM-ready materials tailored to demanding applications and design

requirements.

A cornerstone of this collaboration is the launch of a regional LFAM innovation hub, anchored

by CEAD’s Flexbot and supported by

Interfacial’s material development and processing capabilities. This hub will

provide a platform for customers to engage in full-cycle material evaluation,

print trials, and application-specific development under one roof.

“This partnership gives our clients access to both material

science and LFAM hardware expertise, all aligned to real-world project

requirements,” Masson added.

With growing interest in large-format additive solutions across

industries such as construction, infrastructure, and industrial manufacturing,

Interfacial and CEAD are focused on accelerating the development of scalable,

sustainable materials that enable new applications and drive adoption of LFAM

technologies globally.

“This is a strategic leap forward,” said Andrea Baldolini, Head of Sales at CEAD. “By collaborating closely

with Interfacial, we’re aligning machine performance with material behavior

from the ground up. This synergy enables us to serve new markets more effectively,

with faster development cycles and the ability to create tailored materials for

specific industries and applications.”