Toray Unveils Industry’s First 160 °C-Resistant Polypropylene Release Film to Boost High-Temperature CFRP Prepreg Processing

BY Composights

Published: 30 Jan 2026

Toray Industries has introduced the TORAYFAN 160

C-resistant biaxially oriented polypropylene (OPP) release film, a

material breakthrough targeting the chronic thermal limits of conventional

release consumables in high-performance composite manufacturing. Engineered for

high-temperature carbon

fiber-reinforced plastic (CFRP) prepreg consolidation and complex

molding processes where fluorinated films are standard, this uncoated

OPP film delivers industry-leading thermal

dimensional stability and clean release at cure temperatures up to 160 C

reducing distortion to roughly one-tenth that of typical OPP and minimizing

moisture uptake that degrades prepreg surface integrity and part quality.

By positioning a high-heat polypropylene alternative within

the composites supply chain, Toray is directly addressing tooling efficiency

and defect risk in advanced CFRP production and niche IC substrate workstreams,

aligning with escalating performance and sustainability demands in mobility and

electronics sectors.

A key intended use is as a high-heat-resistant release film

in IC substrate, carbon fiber-reinforced plastic prepreg, and other molding

processes, where fluorinated films are widely used today. Toray will continue

technical development to meet customer application needs.

Manufacturers widely use OPP film in packaging because it resists moisture and stays clear. They also use it as an industrial material in their processes because it releases cleanly and emits little gas. Manufacturing and processing steps are diversifying as electronic devices and lightweight mobility materials evolve, so OPP film must withstand higher temperatures.

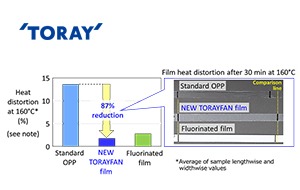

The new TORAYFAN stemmed from reinforcing Toray s high-heat-resistance technology for OPP film and integrating it with a new high-heat-resistance surface technology employing a high-heat-resistance polyolefin resin. This reduced heat distortion to about one-tenth that of standard OPP film at 160 C. It also lowered wettability, which should deliver excellent release properties.

On top of the thermal dimensional stability and release properties, this new film is uncoated and absorbs little moisture. This makes it suitable for demanding applications where even thermal wrinkles or slight contamination from release components during processing, such as thermal lamination, is unacceptable. It also suits applications that cannot tolerate moisture in the film, such as processing battery components in dry rooms or in vacuum equipment used for vapor deposition and sputtering.

Toray will continue to innovate advanced, high-performance materials in keeping with its commitment to delivering new value and contributing to social progress.