Hive Composites Develops Breakthrough Low-Viscosity Thermoplastic for Wind Turbine Blades

BY Composights

Published: 13 Aug 2025

Hive Composites, a leader

in advanced materials design, prototyping and testing, has announced a

breakthrough in thermoplastic composites following a two-year Innovate

UK-funded research project targeting wind turbine blade applications.

With more than 30 years of

expertise in thermoplastics, Gerry Boyce and the Hive Composites team

have long recognised the benefits of the material, including recyclability and

superior mechanical properties. However, the high viscosity of molten

thermoplastics has traditionally limited fibre impregnation without high-pressure

processing, restricting applications to smaller parts with costly tooling.

The research focused on creating

a thermoplastic polymer that would combine low viscosity for fibre infusion,

high mechanical performance, recyclability, compatibility with conventional

thermoset processing, and cost parity with epoxy resins.

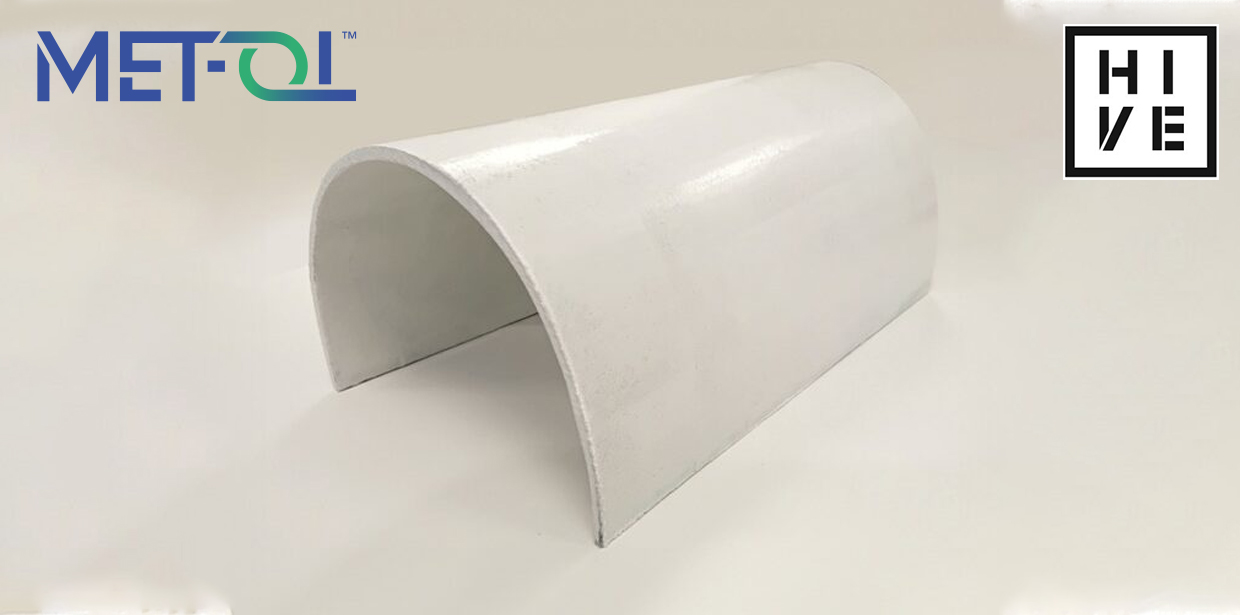

The result is MET-OL , a

proprietary low molecular weight form of polybutylene terephthalate (PBT)

developed using a novel chemical process. Unlike conventional PBT, which melts

at 235 C and requires high-pressure moulding, MET-OL melts at just 140 C

into a highly flowable liquid capable of rapid fabric infusion. Once in the

mould, the material is catalytically converted back into high molecular weight

PBT, delivering the strength, thermal stability and chemical resistance of its

original form.

MET-OL is supplied as a powder

via Hive s spin-off company, Metol Ltd. Comparative testing has shown improved

mechanical performance over epoxy and polyester resins, while Loughborough

University s preliminary Life Cycle Assessment highlights potential sustainability

advantages, particularly through end-of-life recyclability into high-value

applications.

This innovation could transform

manufacturing in sectors ranging from renewable energy and aerospace to

automotive, enabling larger-scale thermoplastic composite structures with lower

production costs and enhanced circularity.

Source: hivecomposites.com