AZL Launches Joint Partner Project to Optimize Thermoplastic Pressure Vessel Production

BY Composights

Published: 07 Aug 2025

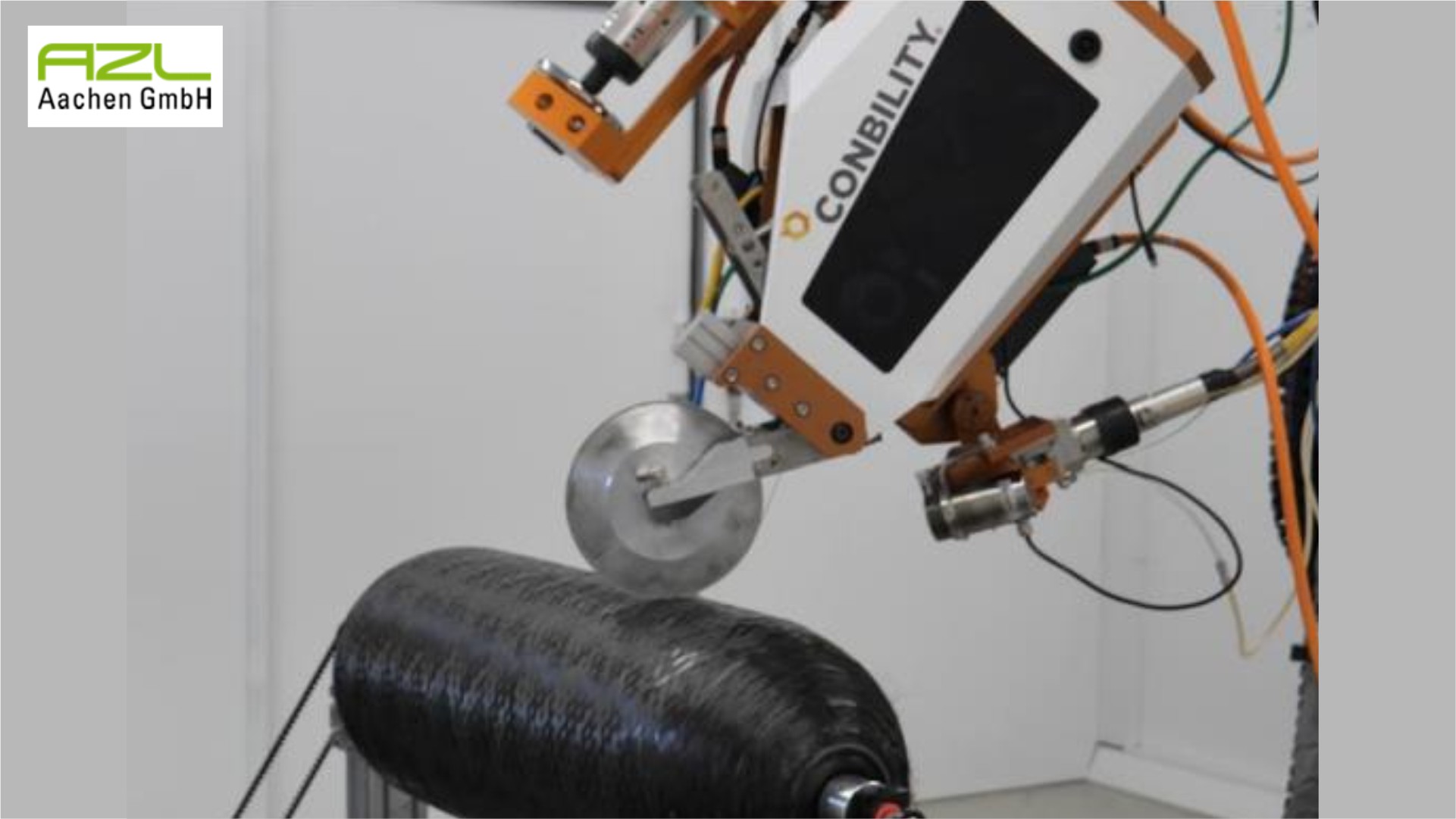

AZL Aachen GmbH has launched a new Joint Partner

Project (JPP) titled Thermoplastic Pressure Vessel Production

Benchmarking of Design-for-Manufacturing Strategies to Optimize Material

Efficiency and Cost . This collaborative engineering initiative aims to

bring together companies across the pressure vessel and composites value

chains to explore next-generation solutions for sustainable high-pressure

storage.

Thermoplastic composites have long been lauded for

their short processing times, recyclability, and design flexibility. However,

directly adapting thermoset-based pressure vessel designs for

thermoplastic production often results in cost and efficiency setbacks. To

address this, AZL s project will adopt a holistic design-for-manufacturing

approach, optimizing vessel designs around thermoplastic material

characteristics to unlock their full technological and economic potential.

Structured as a Joint Partner Project, the initiative

invites companies to co-finance and co-develop the project scope. AZL s

engineering team will evaluate existing manufacturing strategies, propose new

design concepts for hydrogen and compressed natural gas (CNG) vessels,

and benchmark the solutions on key metrics including weight, production cost,

recyclability, and process efficiency.

Participating partners will receive access to detailed

simulation data, concept designs, and standardized evaluation results. The

project also serves as a strategic networking platform where members can

exchange insights, shape project priorities, and gain early access to

innovations.

The project kicks off on July 16, 2025, with an

interactive session where participating companies will define shared goals and

align internal perspectives.

Backed by over a decade of experience in coordinating

collaborative industrial R&D programs, AZL ensures the initiative will be

both technically robust and business-relevant, offering the composite

industry a path forward toward scalable, sustainable pressure vessel

solutions.

Source: azl-aachen-gmbh.de