Toray Demonstrates High-Speed Thermal Welding to Bond Carbon Fiber Reinforced Plastic Aircraft Structures

BY Composights

Published: 04 Feb 2026

Toray Industries has taken a significant step toward

next-generation composite airframe manufacturing by successfully testing a

thermal welding technology that enables rapid, high-strength bonding between

thermoset and thermoplastic CFRP structures. The development directly addresses

one of aerospace composites most persistent bottlenecks, slow, complex joining

processes driven by adhesive bonding and mechanical fastening. By enabling

direct welding between dissimilar CFRP systems, Toray s approach not only

delivers higher joint strength than conventional adhesive methods but also

reduces bonding cycle times by nearly threefold, positioning the technology as

a productivity lever for high-rate composite aircraft programs while offering

potential weight savings through reduced fastener dependency.

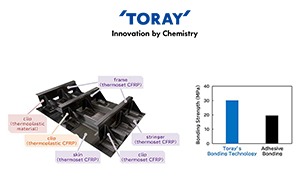

Thermoset CFRP is widely used for primary aircraft structures due to its excellent material properties and long track record of practical use. In recent years, as demands for smaller components and more complex geometries have grown, the use of thermoplastic CFRP, well suited for high rate production and offers high design flexibility, have also expanded. By combining thermoset and thermoplastic CFRP, there are anticipations for new airframes with enhanced performance and productivity. However, such conventional techniques as adhesive bonding and bolted fastening add complexity and slow production, creating a strong need for bonding technologies that improve both productivity and reliability.

Toray drew on years of expertise in CFRP intermediate material (prepreg) manufacturing and in CFRP molding and processing, to develop a thermal welding technology that bonds thermoset and thermoplastic CFRP. This delivers higher bonding strength than conventional adhesive bonding (see note 3 and Figure 1). It also makes bonding for simulated aircraft structures (Figure 2) three times faster than that needed for conventional adhesive bonding and bolted fastening. The technology can also lower aircraft weight by reducing the number of bolt fasteners. Going forward, Toray will accelerate its commercialization efforts in collaboration with aerospace manufacturers.

This technology is the result of the Development of New Innovative Composite Materials and Forming Technologies , supported by the New Energy and Industrial Technology Development Organization (NEDO). Toray will exhibit its breakthrough at nano tech 2026 (the 25th International Nanotechnology Exhibition & Conference) held at Tokyo Big Sight from January 28 through 30, 2026.

Toray has stated in its Sustainability Vision that it is committed to providing innovative technologies and advanced materials to help address global issues. The company will continue to innovate materials and technologies for a carbon-neutral economy, in line with its corporate philosophy of contributing to society through the creation of new value with innovative ideas, technologies and products.