Toray Develops Carbon Fiber Recycling Technology to Strengthen Next-Generation Material Capabilities

BY Composights

Published: 31 Oct 2025

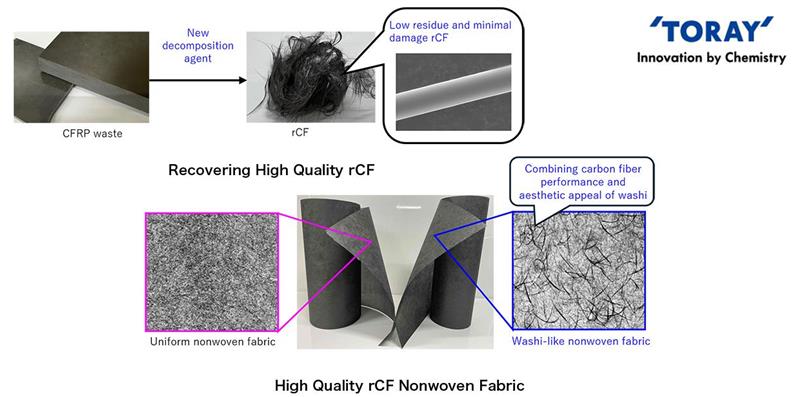

In response to escalating demand across aerospace, energy

and transport sectors, Toray Industries is scaling up its carbon-fibre

composite materials business under the Torayca banner. The company has announced

the development of a recycling technology that can decompose diverse carbon fiber reinforced plastics (CFRP) made from

thermosetting resins while retaining

the strength and surface quality of those fibers. The company drew on this

technology to create a nonwoven fabric employing recycled carbon fibers.

With a renewed focus on ultra-high-strength

fibre grades and industrial-scale

production of large-tow formats, the company is positioning itself to meet

the carbon-neutrality push and

structural-lightweighting imperatives of tomorrow s mobility and energy

infrastructure.

Toray has started providing prototype samples to customers

with a view to them developing performance and decorative materials for diverse

applications, such as automobiles, construction, electricals and electronics,

and daily necessities. The company will push ahead with technical assessments

matching customer needs.

CFRP applications include aircraft and wind turbines.

Chemical recycling as a reducing agent in steel furnaces is gaining traction

for recycling CFRP. Technologies are emerging pyrolyzing waste CFRP at high

temperatures to recover and reuse fibers, with the market expanding

particularly for injection molding applications. To broaden applications, there

is a need for technology that can suppress thermal damage (see note 1) to

recycled carbon fibers and control resin residue (note 2) and that can be applied

to diverse types of waste CFRP.

Toray applied its accumulated expertise in organic synthesis

and polymer polymerization to innovate a decomposition agent that breaks down

degradation-resistant, three-dimensionally crosslinked (note 3) thermosetting

resins at lower temperatures than conventional methods. The company used this

agent to decompose CFRP waste from aircraft, wind turbines, automobiles, and

other sources. The recycled carbon fiber from this process retains over 95% of

the single-fiber tensile strength of petroleum-derived virgin carbon fiber.

Toray expects carbon dioxide emissions from this technology to be less than

half those from manufacturing virgin carbon fiber.

Recycled carbon fiber from this technology is stronger than

conventional counterparts and minimizes fiber breakage in post-processing. Its

low resin residue and excellent surface quality enables processing for more

diverse applications. In particular, efforts to disperse short fibers and

process them into sheet-form nonwoven fabrics have led to success.

The recycled carbon fibers produced using this technology

exhibits controllable water dispersibility, allowing for the fabrication of

uniform nonwoven structures as well as those with distinctive texture

reminiscent of washi (traditional Japanese paper). This fabric combines the

functionality of carbon fiber, including radio frequency shielding and thermal

conductivity, with the aesthetic appeal of washi. Toray aims to expand

applications for this new material across many industries.

This innovative fabric features in the interior and exterior

components of the concept car (vision model) that Mazda Motor Corporation will

exhibit at the Japan Mobility Show at Tokyo Big Sight from October 30 through

November 9.

Toray developed its recycling technology and carbon fiber

nonwoven fabric processing technology as part of a fiscal 2024 through 2025

Ministry of the Environment program to promote establishment of decarbonized

and circular economy.

One goal of the Toray Group Sustainability Vision for 2050 is to contribute to a world where resources are sustainably managed. The company will continue to progress with R&D to help create a circular society, in line with its corporate philosophy of contributing to society through the creation of new value with innovative ideas, technologies and products."

Notes

- Thermal damage (degraded physical and chemical properties) occurs when exposing carbon fibers to high temperatures or oxidization during pyrolysis.

- Residue refers to undecomposed or partially decomposed resin on carbon fiber surfaces during separation.

- Three-dimensional cross-linking results from chemical or physical bonding between polymer chains.