Envalior, General Motors, and Schaeffler Win 2025 SPE Innovation Award in the Powertrain Category for Thin Wall ETC Actuator Gears

BY Composights

Published: 15 Dec 2025

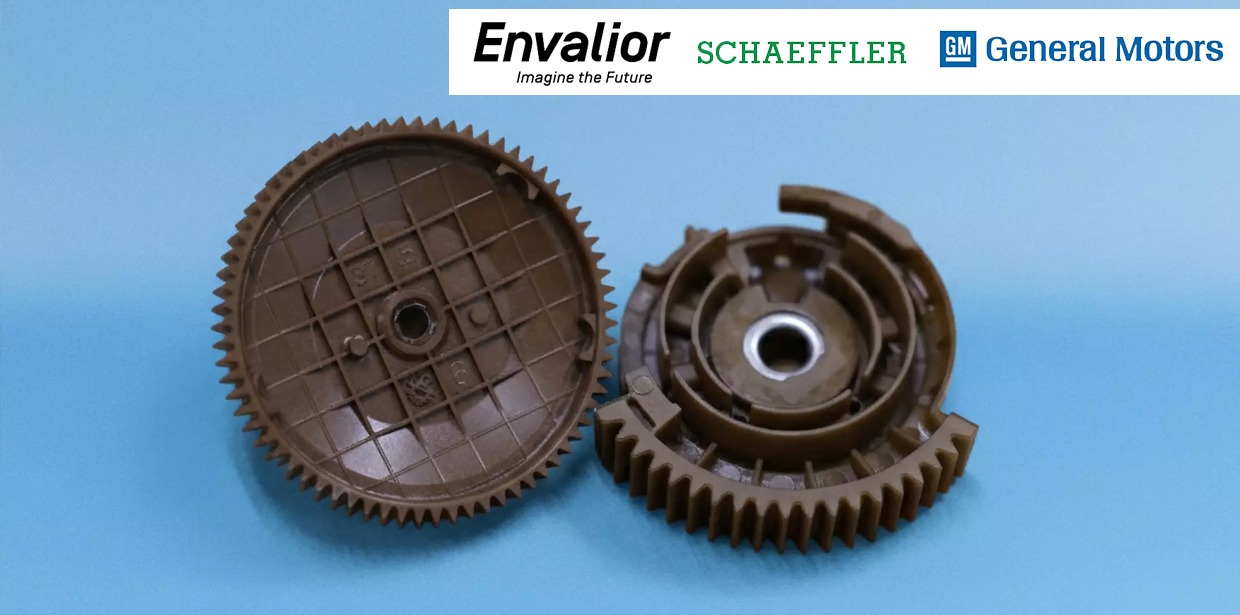

Envalior a global leader in Engineering Materials, in

collaboration with General Motors and Schaeffler AG, have received the

2025 Society of Plastics Engineers (SPE) Automotive Innovation Award in the Powertrain category for an

ultra-thin wall actuator gear built on high-performance, glass-fiber reinforced Stanyl PA46.

This materials-centric breakthrough achieves a 30 % reduction in weight,

enhanced stiffness and wear resistance, and significant cost and packaging

efficiencies compared with conventional metal-dominant designs underscoring

the pivotal role of advanced thermoplastics and composite reinforcement in

next-generation automotive powertrain components.

- Collaboration

recognized for breakthrough Stanyl PA46 thin wall actuator gear

design enabling electronic throttle control to have 30% weight reduction

and cost savings in two of GM s compact SUVs while enhancing stiffness,

wear resistance, and packaging efficiency.

- The

award recognizes the team s innovative material engineering and

cross-industry collaboration in advancing lightweight, high-performance

powertrain components.

Leveraging

Stanyl PA46, Envalior s high-performance polyamide material, the team

successfully developed a thin yet robust actuator gear wall for an electronic

throttle control application. The innovative mid-gear design ensures precise

pedal-to-throttle response and excellent impact absorption, virtually

eliminating tooth breakage.

This initiative brought together a team of experts from

every discipline, and the collaboration was exceptional, said Tony Padden, Envalior

Stanyl Technical Application Manager NA. We overcame challenges, met

ambitious targets, and delivered a solution that set a new industry benchmark.

I m proud to have been part of such a rare and successful effort."

By combining high-flow W&F-optimized Stanyl PA46 and 50% or 60% glass fiber reinforcement, followed by post-mold heat treatment, the team achieved precise gear geometry and optimized mechanical gear performance.

The resulting thin wall actuator gear design delivers:

- 30% higher stiffness

- 20% increased wear resistance

Enabling the electronic throttle control design to provide when compared to a conventional 1.5 mm-thick actuator gear wall:

- 30% weight reduction

- 20% cost reduction

- 20% space reduction

This award-winning application is featured in two of GM s 2025 model year compact SUVs, with Envalior as the material supplier and Schaeffler AG serving as the system supplier and material processor.

This project exemplifies the power of collaboration and innovation across the value chain, said Jose Chirino, Envalior Technical Director - Americas. Together with GM and Schaeffler, we ve advanced what s possible in precision powertrain components by combining lightweight design with exceptional mechanical performance and reliability.