Toray Validates All-Carbon CO2 Separation Membrane Cuts Moisture Removal Costs in Biogas Purification by 70%

BY Composights

Published: 22 Jan 2026

Toray

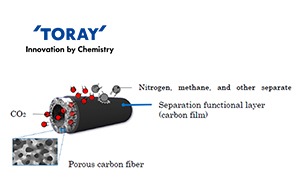

Industries has validated an all-carbon gas separation membrane built on

a carbon fiber based composite architecture, marking a notable expansion

of composite materials into functional membrane systems. The membrane

integrates a porous carbon fiber support with a thin carbon separation layer,

delivering high chemical resistance and stable performance under moisture-rich

biogas conditions.

Successfully

demonstrated at commercial scale in Japan, the technology highlights how carbon

fiber composites are increasingly being engineered beyond structural roles,

enabling cost-efficient gas separation and supporting decarbonisation pathways

in energy and industrial processing. The company confirmed that moisture

removal costs with this technology are around

70% lower than those of existing technologies.

Global

energy shortages and the push to decarbonize have increased demand for more

efficient CO separation. Toray develops all-carbon CO /methane separation

membranes that resist chemicals and separate gases. The company targets natural

gas and biogas purification and CO capture from industrial exhaust. Biogas

purification turns biogas into biomethane by removing impurities from gas made

when waste and other feedstocks ferment. Operators must remove moisture as well

as CO . But polymer and zeolite membranes in conventional systems break down on

exposure to moisture, so facilities must first dry the gas with adsorbents.

That extra step raises costs and makes it hard to scale up methane

purification.

Toray looks to apply this technology beyond biogas to include streamlining natural gas purification, CO separation and capture from industrial exhaust gases, and carbon dioxide capture, utilization and storage.

The company will showcase its technology at Nano Tech 2026, which will be at Tokyo from Wednesday, January 28, through to Friday, January 30, 2026.

Toray will continue to pursue research and development in keeping with its commitment to delivering new value and contributing to social progress to help resolve global environmental, resource, and energy issues and contribute to a carbon-neutral and sustainable economy. Part of the development work for its new technology was through a project funded by the New Energy and Industrial Technology Development Organization.

Source Toray