Phoebus Project Leverages Carbon-Fibre Tanks to Tame Hydrogen’s Smallest Molecule

BY Composights

Published: 04 Nov 2025

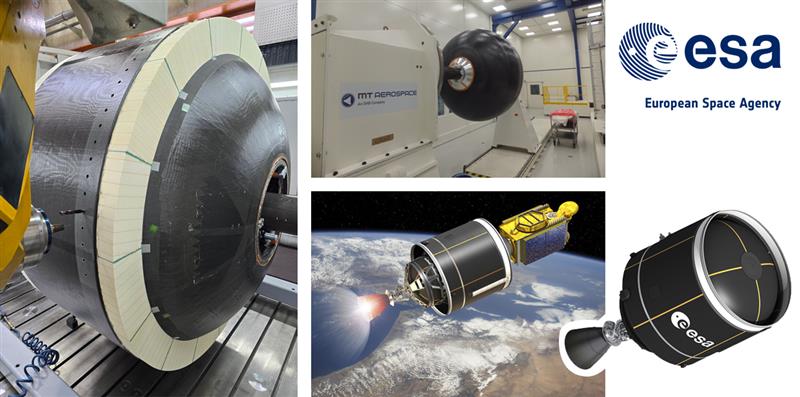

In a significant leap for launch-vehicle materials

engineering, the European Space Agency s

(ESA) Phoebus project has

demonstrated that carbon-fibre-reinforced-plastic (CFRP) cryogenic tanks can

safely contain liquid hydrogen the smallest molecule in the universe at

temperatures near -253 C without

leaking.

The Phoebus project, led by the ESA in collaboration with ArianeGroup

and MT Aerospace, aims to evaluate the feasibility and advantages of

replacing the metallic tanks on ESA s Ariane 6 upper stage with carbon-fibre-reinforced-plastic (CFRP) tanks. While this lightweight material

offers the possibility of saving several

tonnes of mass, such an approach has never been implemented before and

presents significant technical challenges.

With a 2-metre-diameter,

2 600-litre composite hydrogen tank

nearing production and testing scheduled for April 2026, the move away from metallic tanks on the Ariane 6 upper

stage heralds substantial mass savings and a competitive edge in space-launch

economics.

Let it Freeze

Hydrogen is the smallest molecule in the Universe, and when

used as fuel on the Ariane 6 rocket it has to be cooled to 253 C, just 20

degrees above absolute zero, the coldest temperature in the Universe.

Generally, carbon fibre composites do not like it that cold,

like your skin in winter. With the cold your skin gets dry and brittle such

that when you move it can crack. This is the same for carbon fibre tanks: when

filled with cool propellants under pressure, small cracks can form which is not

what you want on a rocket tank.

With these extreme conditions the Phoebus project team

overcame many technical hurdles not only on development and tank concepts but

also on measurement - there are no off-the-shelf devices that accurately

measure miniscule leak rates at cryogenic temperatures as low as 253 C.

Phoebus has already proved it is possible: small 60-l

demonstration bottle tanks have shown that carbon-fibre

reinforced-plastic can hold hydrogen in liquid form without leaking.

Increasing the Ice-Cold Pressure to Cracking Point

Now the Phoebus team is working on a larger version with an

updated design that will hold almost 2600 litres. This 2-metre diameter

hydrogen tank will be tested by filling it with hydrogen next year.

The tank completed the first manufacturing steps on its

inner tank pressure vessel at MT Aerospace in Augsburg, Germany in September

2025 with production expected to be finished in December. ArianeGroup will be

responsible for the testing and their engineers are working on the design of

the test facility.

A test campaign is planned in April next year. Despite being kept at 253 C hydrogen catches fire very easily so needs careful handling, special skills and strict safety rules to make sure everything goes smoothly. The testing will be conducted at a test site of ArianeGroup in Trauen, Germany. The tank will be pushed step-by-step to its breaking point, creating the cracking effect but no further: the team will stop before reaching the complete failure point of the tank. The work on the new test site kicked-off in February 2025, with a preliminary design confirmed in June 2025. A critical design review by the end of this year will allow for the start of the civil works at the site.

Phoebus is part of ESA s Future Launchers Preparatory Programme (FLPP), that helps develop the technology for future for space transportation systems. By conceiving, designing and investing in technology that doesn t exist yet, this programme is reducing the risk entailed in developing untried and unproven projects for space.