NC State Researchers Unveil Self-Healing Composites with Century-Scale Lifecycle Potential

BY Composights

Published: 26 Jan 2026

North Carolina State

University (NCSU) researchers

have engineered a next-generation self-healing fiber-reinforced composite

that is tougher than materials currently used in aircraft wings, turbine

blades, etc. The material can also repair interlaminar damage in situ and

maintains structural performance after 1,000 fracture-heal cycles, potentially

extending service lives by orders of magnitude beyond conventional FRP

materials used in aircraft, automobiles, wind turbines and spacecraft.

By integrating 3D-printed thermoplastic healing

interlayers and embedded carbon heater networks to thermally remend delaminations

on demand, the technology targets the persistent Achilles heel of laminated

composites, interlaminar delamination, and models suggest material lifespans of

125 500 years under realistic repair intervals.

This would significantly drive down costs and labor

associated with replacing damaged composite components, and reduce the amount

of energy consumed and waste produced by many industrial sectors because

they ll have fewer broken parts to manually inspect, repair or throw away, says Jason Patrick, corresponding author of

the paper and an associate professor of civil, construction and

environmental engineering at North Carolina State University.

At issue are fiber-reinforced polymer (FRP) composites,

which are valued for their high strength-to-weight ratio and are commonly used

in aircraft, automobiles, wind-turbines, spacecraft and other modern structural

applications. FRP composites consist of layers of fibers, such as glass or

carbon fiber, that are bonded together by a polymer matrix, often epoxy. The

self-healing technique developed by the NC State researchers targets

interlaminar delamination, which occurs when cracks within the composite form

and cause the fiber layers to separate from the matrix.

Delamination has been a challenge for FRP composites since

the 1930s, Patrick says. We

believe the self-healing technology that we ve developed could be a long-term

solution for delamination, allowing components to last for centuries. That s

far beyond the typical lifespan of conventional FRP composites, which ranges

from 15-40 years.

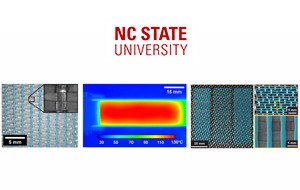

The self-healing material resembles conventional FRP

composites, but with two additional features. First, the researchers 3D-print a

thermoplastic healing agent onto the fiber reinforcement, creating a

polymer-patterned interlayer that makes the laminate two to four times more

resistant to delamination. Second, the researchers embed thin, carbon-based

heater layers into the material that warm up when an electrical current is

applied. The heat melts the healing agent, which then flows into cracks and microfractures

and re-bonds delaminated interfaces restoring structural performance.

To evaluate long-term healing performance, the team built an

automated testing system that repeatedly applied tensile force to an FRP

composite producing a 50 millimeter-long delamination, then triggered thermal

remending. The experimental setup ran 1,000 fracture-and-heal cycles

continuously over 40 days, measuring resistance to delamination after each

repair. In other words, the researchers cracked the material in the exact same

way, healed it, and then measured how much load the material could handle before

delaminating again. And they did that 1,000 times, an order-of-magnitude

beyond their prior record.

We found the fracture resistance of the self-healing

material starts out well above unmodified composites, says Jack Turicek, lead author of the paper and a graduate student at

NC State. Because our composite starts off significantly tougher than

conventional composites, this self-healing material resists cracking better

than the laminated composites currently out there for at least 500 cycles. And

while its interlaminar toughness does decline after repeated healing, it does

so very slowly.

In real-world scenarios, healing would only be triggered

after the material is damaged by hail, bird strikes or other events, or during

scheduled maintenance. The researchers estimate the material could last 125

years with quarterly healing or 500 years with annual healing.

This provides obvious value for large-scale and expensive

technologies such as aircraft and wind turbines, Patrick says. But it could

be exceptionally important for technologies such as spacecraft, which operate

in largely inaccessible environments that would be difficult or impossible to

repair via conventional methods on-site.

The study also shed light on why recovery slowly declines

over time. With continued cycling, the brittle reinforcing fibers progressively

fracture creating micro-debris that limits rebonding sites. In addition,

chemical reactions where the healing agent interfaces with the fibers and

polymer matrix decline over time. Even so, modeling suggests the self-healing

will remain viable over extremely long time scales.

Despite the inherent chemo-physical mechanisms that slowly reduce healing efficacy, we have predicted that perpetual repair is possible through statistical modeling that is well suited for capturing such phenomena, says Kalyana Nakshatrala, co-author of the paper and the Carl F. Gauss Professor of Civil and Environmental Engineering at the University of Houston.

Patrick has patented and licensed the technology through his startup company, Structeryx Inc. He says, We re excited to work with industry and government partners to explore how this self-healing approach could be incorporated into their technologies, which has been strategically designed to integrate with existing composite manufacturing processes.

The paper, Self-healing for the Long Haul: In situ Automation Delivers Century-scale Fracture Recovery in Structural Composites, is published in the Proceedings of the National Academy of Sciences. First author of the paper is Jack Turicek, a Ph.D. student at NC State. The paper was co-authored by Zach Phillips, a Ph.D. student at NC State, and Kalyana Nakshatrala, the Carl F. Gauss Professor of Civil and Environmental Engineering at the University of Houston.

This work was done with support from the Strategic Environmental Research and Development Program (SERDP) through grant W912HQ21C0044 and from the National Science Foundation, under grant 2137100.