Firefly’s Alpha Block II Upgrade Reinforces Carbon Composite Structures for Higher Launch Reliability

BY Composights

Published: 25 Jan 2026

Firefly Aerospace a market leading space and defense

technology company, announced Alpha

Block II configuration upgrade, underscoring the growing role of carbon

fiber composite structures in next-generation launch vehicles, with

targeted enhancements to structural strength, reliability, and

manufacturability. The updated design re-optimizes composite airframe elements

produced using automated fiber placement, enabling higher performance margins

while maintaining lightweight efficiency, critical for responsive launch

operations. While positioned as a vehicle-level upgrade, the announcement

highlights how continuous refinement of aerospace-grade composite structures

remains central to launch system scalability and cost control.

The Block II upgrade has been part of Firefly s strategic

growth plan to meet the evolving needs of the growing global launch market and

further supports Firefly s culture of continuous improvement with a focus on

enhanced safety, quality, and reliability, said Jason Kim, CEO of Firefly Aerospace. Firefly worked closely

with customers and incorporated data and lessons learned from our first six

Alpha launches and hundreds of hardware tests to make upgrades that increase

reliability and manufacturability with consolidated parts, key configuration

updates, and stronger structures built with automated machinery.

In addition to improving reliability and production rate,

Block II is designed to expand Alpha s deployable launch capabilities for

critical responsive space missions, such as hypersonic testing, national

security missions including Golden Dome, and commercial satellite launches for

domestic and international customers.

The planned Block II upgrades set to launch on Alpha Flight

8 include the following:

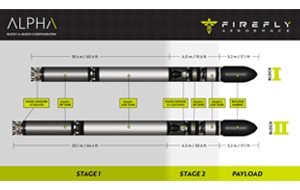

- Increased

length and structural strength: Increasing Alpha s length from

approximately 97 feet to 104 feet

with optimizations for rapid manufacturing on Firefly s Automated Fiber

Placement machine and increased strength of all carbon composite

structures.

- Consolidated

in-house batteries and avionics: Replacing off-the-shelf

batteries and avionics with a consolidated system built in-house and used

across Firefly s spacecraft and rockets for increased schedule,

reliability, and production efficiencies.

- Optimized propellant tanks: Improving thermal protection system for added reliability and optimizing the liquid oxygen and RP-1 tank configurations to increase stage burn time.

Some of these upgrades, including the in-house avionics and thermal improvements, will be tested on Alpha Flight 7. The first stage of the vehicle was recently delivered to Firefly s launch site at the Vandenberg Space Force Base, and the Firefly team is now conducting final integration with the second stage and payload faring ahead of the static fire and launch.

In addition to supporting customer objectives, Firefly is utilizing Flight 7 as an opportunity to test key systems ahead of the full Block II upgrade on Flight 8, said Adam Oakes, Vice President of Launch at Firefly Aerospace. This approach allows us to accelerate our planned Block II timeline and validate the improvements designed to enable more mass savings, optimize production, and increase reliability across the entire Alpha vehicle. Our flight-proven Reaver and Lightning engines and carbon composite structures continue to be the backbone of this rocket, so that core technology doesn t change.