DLR Achieves Breakthrough in Ultra-Thin CF-LMPAEK AFP Laminates Under Project NATURE

BY Composights

Published: 03 Dec 2025

The German Aerospace Center (DLR) has achieved a significant milestone in the NATURE programme

with the world s first Automated Fibre

Placement (AFP) laminates manufactured using ultra-thin CF-LMPAEK

prepreg plies.

Developed by Fukuvi

Chemical Industry Co., Ltd., the material measures just 45 m per ply,

containing as few as seven fibres in the vertical direction nearly one-third

the thickness of standard CF-LMPAEK.

This leap in material architecture unlocks three times

the fibre-orientation flexibility, enabling highly optimised layups for

next-generation aerospace and space structures. Early trials have delivered

excellent consolidation quality, validating the material s suitability for

lightweight, high-performance thermoplastic composite structures.

Funded by the German Federal Ministry for Economic Affairs

and Energy, NATURE targets low-emission helicopter structures and brings

together Airbus Helicopters, Fraunhofer IGCV, and TU Dresden. More performance

data and application insights are expected as the programme advances.

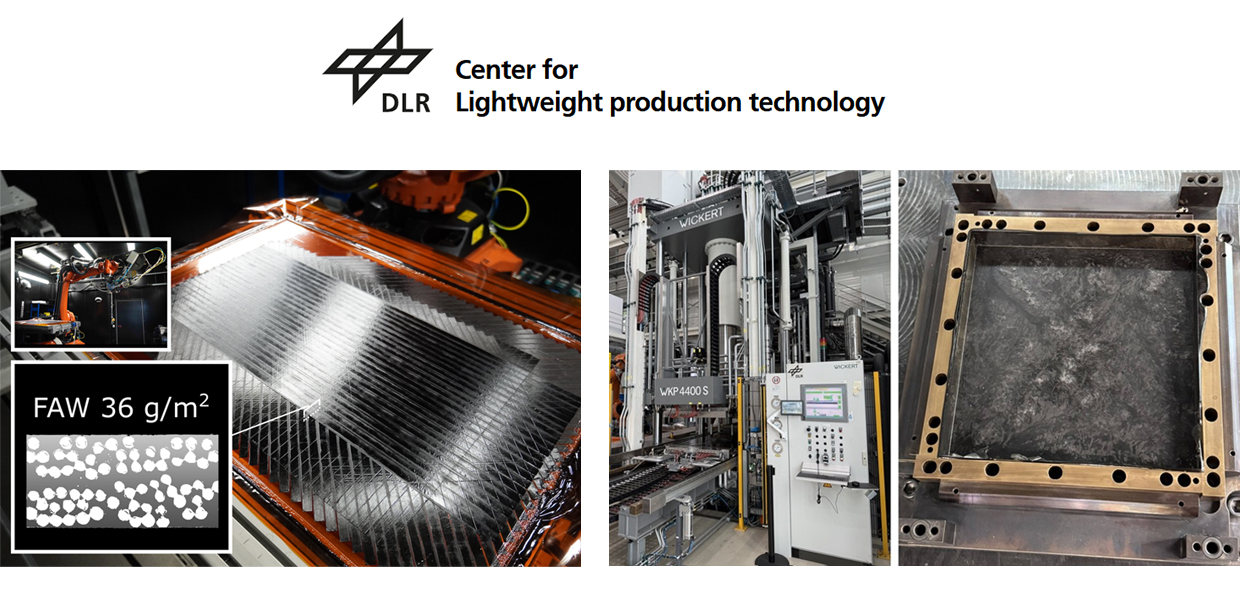

Making the next generation of composite structures for space and aviation lighter and more efficient requires re-thinking not only the structure, but also the material itself. Our team has recently completed a major milestone in the project NATURE, using Automated Fibre Placement (AFP) to manufacture laminates from very thin plies CF-LMPAEK with excellent results.

The project NATURE is funded by the German Federal Ministry for Economic Affairs and Energy (Federal Ministry for Economic Affairs and Energy). The project focuses on the production of new lightweight helicopter structures for lower emission aviation and includes partners such as Airbus Helicopters, Fraunhofer IGCV, and Technische Universit t Dresden.