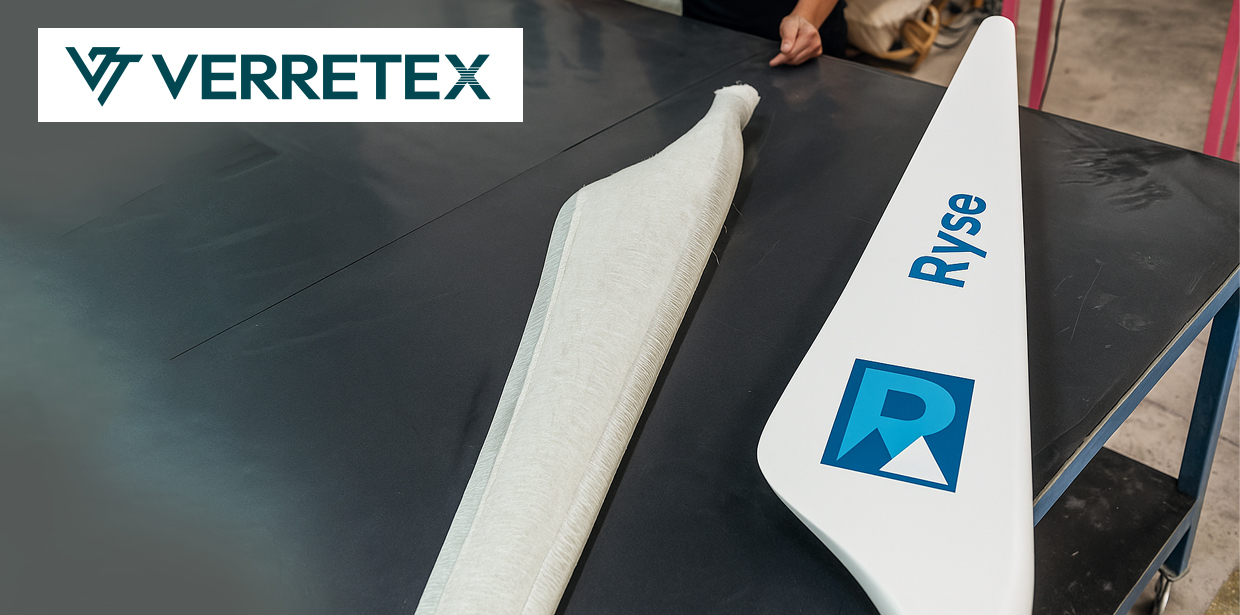

Verretex and Ryse Energy Prove Feasibility of Recycled Glass-Fiber Textiles

BY Composights

Published: 04 Sep 2025

Verretex SA, an EPFL spin-off specializing in

regenerated glass-fiber textiles, and Ryse Energy, a global leader

in small wind turbines and hybrid off-grid systems, have successfully completed

a pilot study proving that Verretex s 100% recycled glass-fiber textile can

directly replace virgin glass-fiber fabrics in wind turbine blade

production.

The trial, conducted at Ryse Energy s manufacturing facility

in Spain under the leadership of Neil Baxter, Technical Composite Specialist,

confirmed that Verretex s material could be processed using existing lay-up and

curing methods with no modifications to tooling or cycle times. The resulting

blades achieved the required strength, stiffness, and durability benchmarks

for small wind turbine applications, aligning with IEC 61400-2 standards.

Our team was able to integrate Verretex s recycled textile

seamlessly, and the resulting test blades met performance requirements, said

Baxter. This shows the real-world potential of recycled composites in

renewable energy manufacturing.

A Life-Cycle Assessment (LCA) by TECH-FAB Europe (via

PwC) highlights the significance of this achievement: 89% of a fabric s

carbon footprint comes from glass fiber production. By avoiding virgin

fiber production, Verretex s regeneration process cuts emissions at the most

impactful stage of the value chain.

Mitchell Anderson, CEO & Co-founder of Verretex,

emphasized: This pilot validates Verretex as a true drop-in solution for blade

makers. We regenerate end-of-life and scrap glass fibers into virgin-like,

low-carbon textiles that fit seamlessly into existing processes no

retraining, no retooling.

Key Outcomes of the Pilot

- Drop-in

compatibility: No changes to Ryse s equipment or production cycles.

- Mechanical

performance: Blades met Ryse s strength and stiffness standards.

- Circular

economy impact: Regenerated textiles reduce waste and lower CO2

emissions without energy-intensive remelting.

Next Steps

Following the pilot, Verretex plans to scale production

capacity to meet industry demand and reduce costs, while Ryse Energy

intends to integrate circular materials across its global manufacturing

sites in Spain, Europe, and the US.

The collaboration marks a critical step toward low-carbon

wind turbine blades, aligning renewable energy production with circular

economy principles and setting a precedent for sustainable composites adoption

at scale.

Source: www.verretex.com