Sensory Consolidation Roller for Laser-Based Automated Fiber Placement

BY Composights

Published: 14 Jul 2025

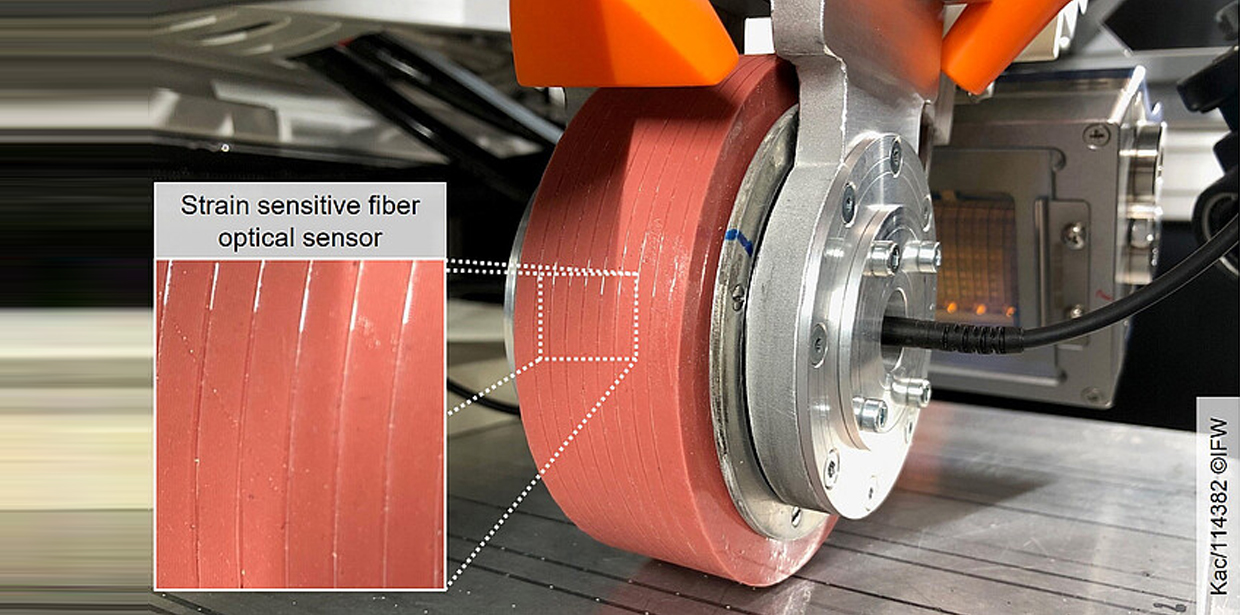

As part of the InSiTe project funded by the German Research

Foundation (DFG), the Institute for Production Engineering and Machine

Tools (IFW) has developed and researched an innovative strain-sensitive

consolidation roller for laser-based

automated fiber placement (LAFP).

The roller s sensitivity comes from glass fiber sensors embedded in

the roller s elastic surface, which detect Rayleigh backscattering

of laser light to measure strain with high spatial resolution, down to 0.65 mm between data points. This

enables precise monitoring of thermal and mechanical loads critical to

producing high-quality, recyclable

thermoplastic composites.

To maximize accuracy, IFW developed methods to compensate for disturbance variables inherent to the LAFP process,

such as laminate thickness and changing boundary conditions. The integration

approach, embedding glass fibers in

grooves using elastic silicone adhesives, demonstrated the highest strain

sensitivity in experimental trials.

A thermodynamic model of the LAFP process was also created to calibrate the sensor and correlate measured

strain with temperature data. The final validation of the sensory

consolidation roller is planned over the coming weeks in real production of a

flat laminate, marking a milestone in process control and quality assurance for

thermoplastic composite manufacturing.

Source: www.ifw.uni-hannover.de