Rock West Composites Develops Low-Dielectric Radome Prototype for Georgian Aerospace

BY Composights

Published: 14 Aug 2025

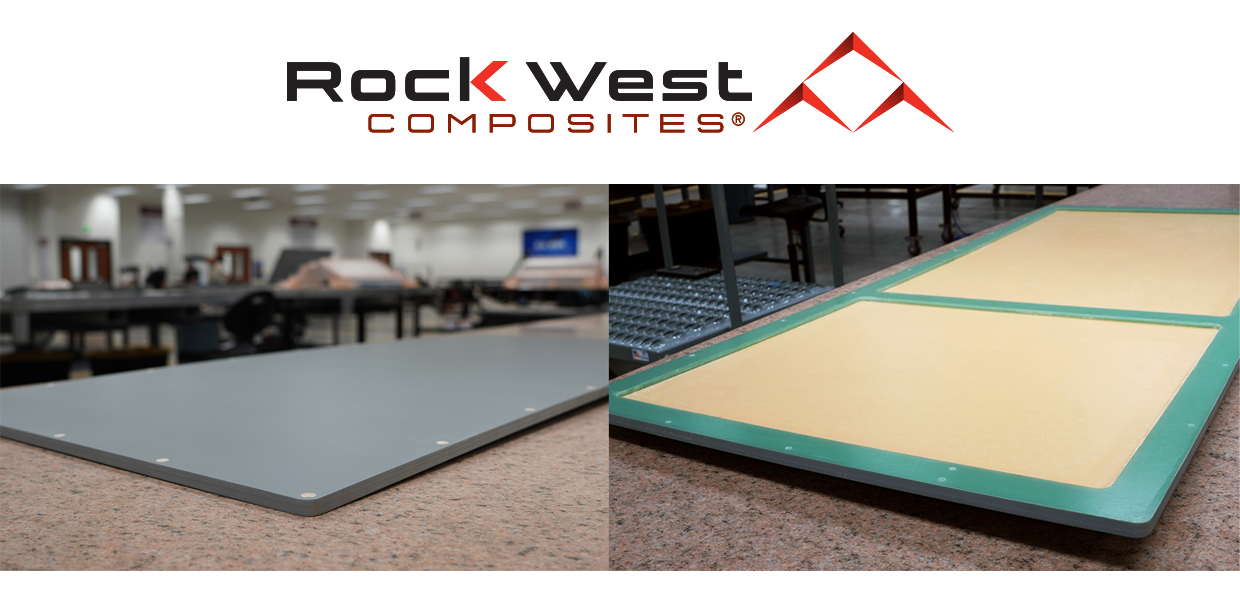

Rock West Composites (RWC)

has successfully completed a prototype radome for Georgian Aerospace, LLC,

leveraging an innovative low-dielectric epoxy prepreg on quartz fabric that

delivers comparable RF performance at a reduced cost versus traditional

materials. The radome passed RF testing to target values, performing

competitively in the 17.7 21.2 GHz and 27.5 31 GHz ranges, with

view angles as low as 25 .

This marks RWC s first

application of a recently NCAMP-certified material developed by Renegade

Materials (Miamisburg, OH). The radome uses RM-2014-LDk-Tk 4581 8HS

Quartz combined with Rohacell foam core in a sandwich configuration,

offering close dielectric compatibility to RWC s preferred materials at a lower

cost. The prototype was produced without tooling under a compressed

schedule, enabling systems-level RF testing while meeting delivery deadlines.

Adam Saunders, Program Manager

at RWC, stated, Usage of this material is exciting as it further enhances

RWC s capability to quickly manufacture highly optimized radome panels at the

best value proposition for our customers. The cost efficiency also expands the

accessibility of an optimized radome to adjacent markets.

Source: www.rockwestcomposites.com