KCL Partners with CEAD to Advance Sustainable Large-Format 3D Printing

BY Composights

Published: 14 Aug 2025

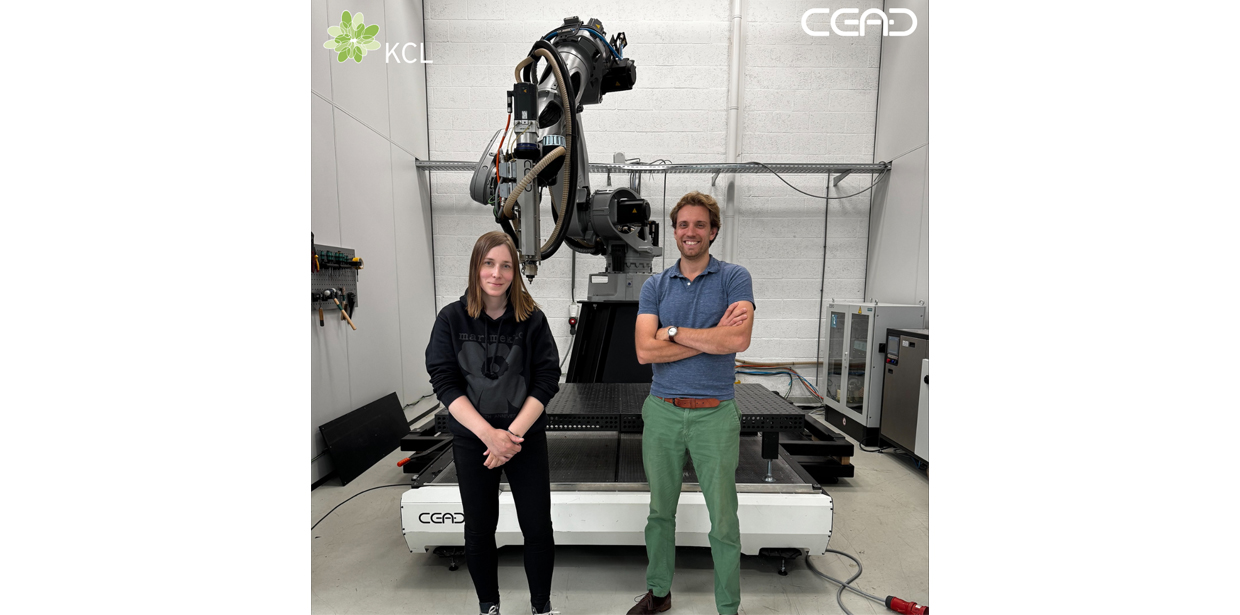

KCL has announced a

strategic partnership with CEAD, a global leader in large-format

additive manufacturing (LFAM) technology, to accelerate sustainable

production in 3D printing. KCL s Formi biocomposite materials

have been successfully tested on CEAD s hybrid LFAM systems, confirming

full compatibility and unlocking new opportunities for bio-based, circular

manufacturing.

KCL Formi replaces traditional carbon

and glass fibers with patented cellulose pulp fiber compositions

combined with thermoplastics, delivering durability, recyclability, and safer

processing. Key benefits include eco-efficiency, outdoor durability, low

shrinkage for faster printing, and easy post-processing.

According to Eve Saarikoski,

Development Manager at KCL, By replacing traditional reinforcement

fibers with cellulose, we re enabling a new class of materials that are strong,

durable, recyclable, and safer to process.

Bob Leutscher, Sales

Area Manager at CEAD, added, KCL s biocomposite materials bring

exciting new possibilities to large-format 3D printing, aligning perfectly with

the demand for sustainable manufacturing.

Source: kcl.fi