KCL Launches Open Access Piloting Services

BY Composights

Published: 19 Aug 2025

KCL has introduced open

access piloting services to support R&D teams in the development and

validation of sustainable high-barrier materials. The services leverage

KCL s state-of-the-art roll-to-roll co-extrusion and lamination line, enabling

hands-on testing of fossil-free, bio-based, and recycled polymers for

functional barrier coatings.

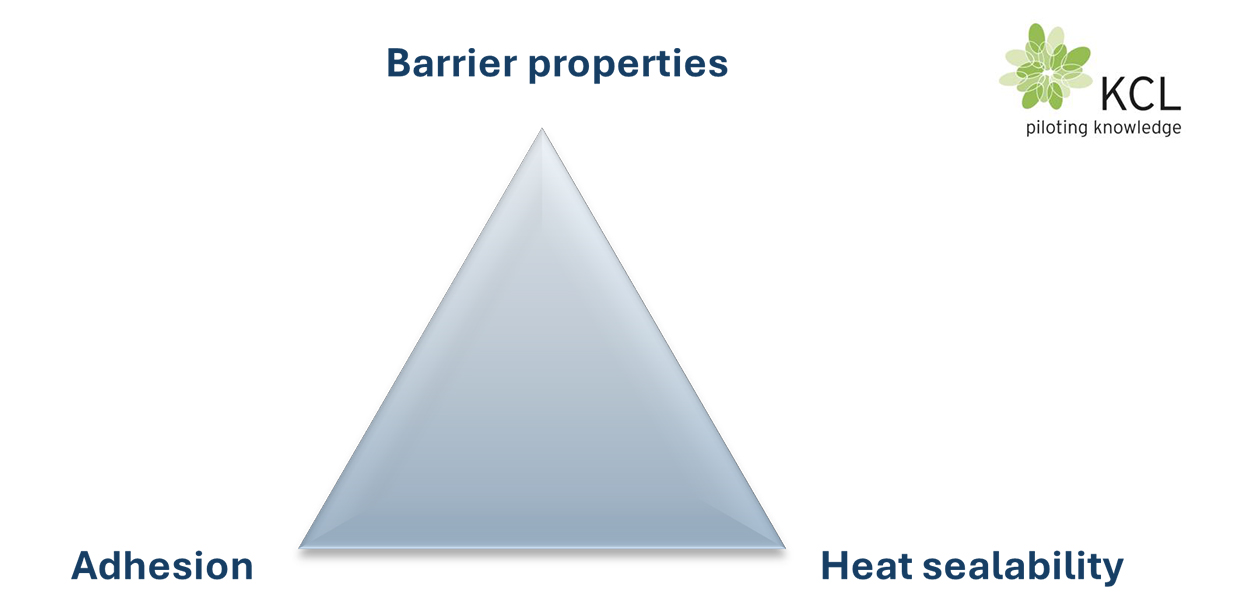

The pilot line allows iterative

testing of polymer formulations and material combinations under

production-like conditions. With quick parameter adjustments, multilayer

experimentation, and compatibility screening, R&D teams can target key

properties such as water vapor, oxygen, grease, and aroma resistance, as well

as adhesion and heat sealability.

Backed by a comprehensive

laboratory for barrier, mechanical, thermal, and seal testing, KCL bridges the

gap between lab-scale concepts and industrial-scale applications. The

integrated setup enables researchers to refine formulations, validate

performance, and reduce development risks with data-rich feedback.

By combining advanced

infrastructure with expert technical support, KCL provides an agile

environment for piloting sustainable packaging innovations, from

compostable barriers to recyclable structures.

Source: kcl.fi