IKV Develops New Method to Measure Resin Residence Time in Pultrusion Profiles

BY Composights

Published: 09 Sep 2025

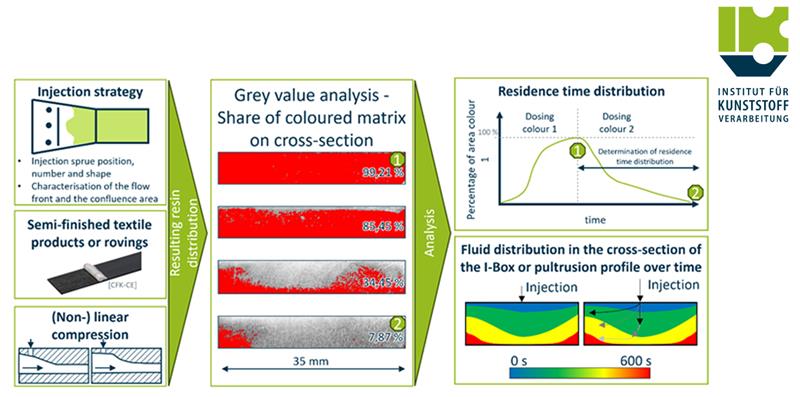

The Institute for Plastics Processing (IKV) at RWTH

Aachen University is pioneering a new experimental method to measure

resin residence time and its local variation across the cross-section

of pultrusion profiles. The approach is designed to improve

understanding of flow fields in injection box technology, which

is increasingly replacing open impregnation baths in the production of lightweight

fiber-reinforced plastic (FRP) components.

According to IKV, injection boxes enhance product

quality and boost process productivity, especially for highly

reactive matrix systems. Previous research examined geometric influences

on backflow, but the role of injection strategies on production

speed and impregnation quality remains underexplored.

In the study, IKV uses an impulsive color change in

the resin during pultrusion to visualize the flow field. Cross-sections

are analyzed for color distribution, and digital image correlation

maps the temporal variation, delivering new insights into resin flow

and impregnation dynamics.

Findings show potential in combining injection box

geometry, injection strategy, and semi-finished textile products

to improve process efficiency and component quality.

The first project meeting will be held at IKV

on September 23, 2025. The research is part of IGF project

(01IF23502N), funded by the Federal Ministry for Economic Affairs and

Energy (BMWi) under the Industrial Collective Research (IGF)

program.

Source: ikv-aachen.de