Holy Technologies Selects Plataine to Enable Scalable Serial Production of Carbon Fiber Components

BY Composights

Published: 10 Sep 2025

Holy Technologies, a

fast-growing German manufacturer of sustainable, high-performance carbon

fiber components, has chosen Plataine, a leading provider of AI-driven

manufacturing optimization solutions, to support its transition into serial

production. The partnership will enhance scheduling, traceability, and

production control across Holy s operations.

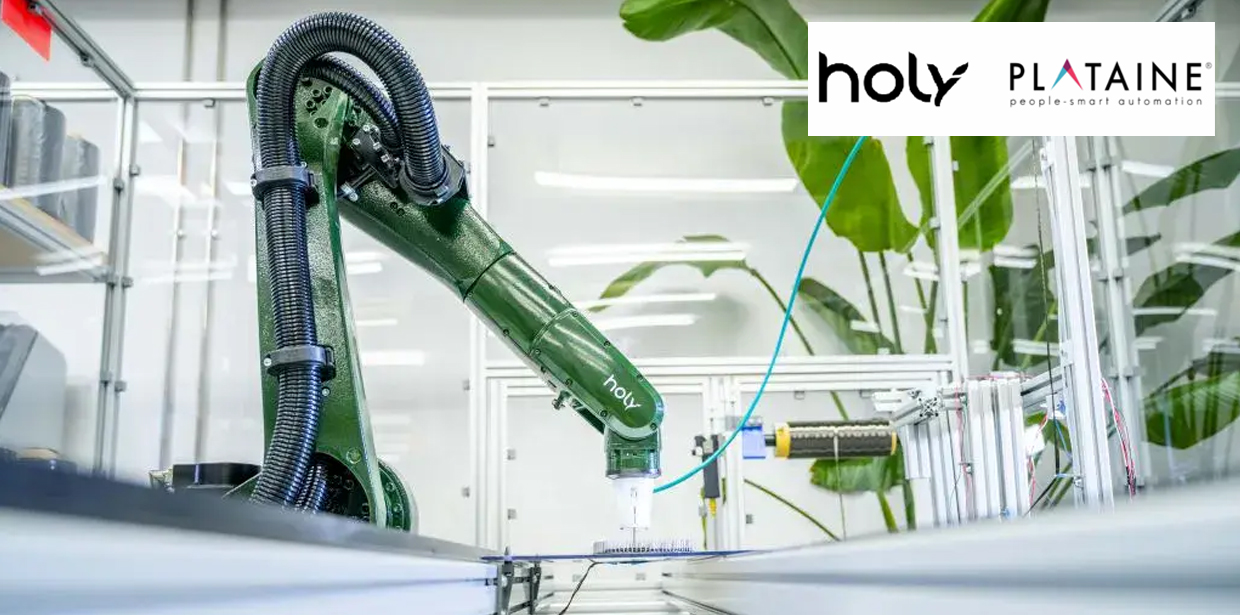

Holy Technologies, founded in Hamburg,

is pioneering carbon fiber manufacturing with its proprietary Infinite

Fiber Placement (IFP) process. This fully automated robotic system places

continuous carbon fibers along pre-calculated paths, enabling components with

complex geometries, tailored mechanical properties, and up to 30% weight

reduction compared to conventional methods. The approach is particularly

attractive for automotive, aerospace, industrial machinery, and orthopedic

applications, where lightweight and strong materials are critical.

To ensure smooth scaling, Holy

Technologies selected Plataine s AI-powered Production Scheduler, which

optimizes workstation loads, shift planning, and predictive maintenance while

providing real-time quality monitoring. The system also ensures comprehensive

traceability of molds, tools, and components, supporting compliance and

minimizing rework.

With Plataine, we gain the

digital backbone to scale our manufacturing without compromising flexibility or

sustainability, said Bosse Rothe Frossard, Founder & CEO of Holy

Technologies.

Avner Ben-Bassat, President

& CEO of Plataine, added: Holy Technologies Infinite Fiber Placement

process is a game-changer for sustainable composites. Our AI agents will

help them grow efficiently and competitively.

The collaboration positions Holy

Technologies to reduce planning effort, improve on-time delivery, and establish

a robust digital foundation for long-term growth in the advanced composites

industry.

Source: www.plataine.com