Greene Tweed Secures 10-Year Strategic Agreement for Advanced Thermoplastic Composite Engine Components

BY Composights

Published: 12 Aug 2025

Greene Tweed, a global

leader in advanced materials and high-performance solutions, has signed

a 10-year, multi-million-dollar strategic agreement with one of the

world s largest commercial engine and integrated systems manufacturers. The

deal strengthens a long-standing partnership and reinforces Greene Tweed s

position as a trusted supplier of thermoplastic composite components for

advanced aerospace applications.

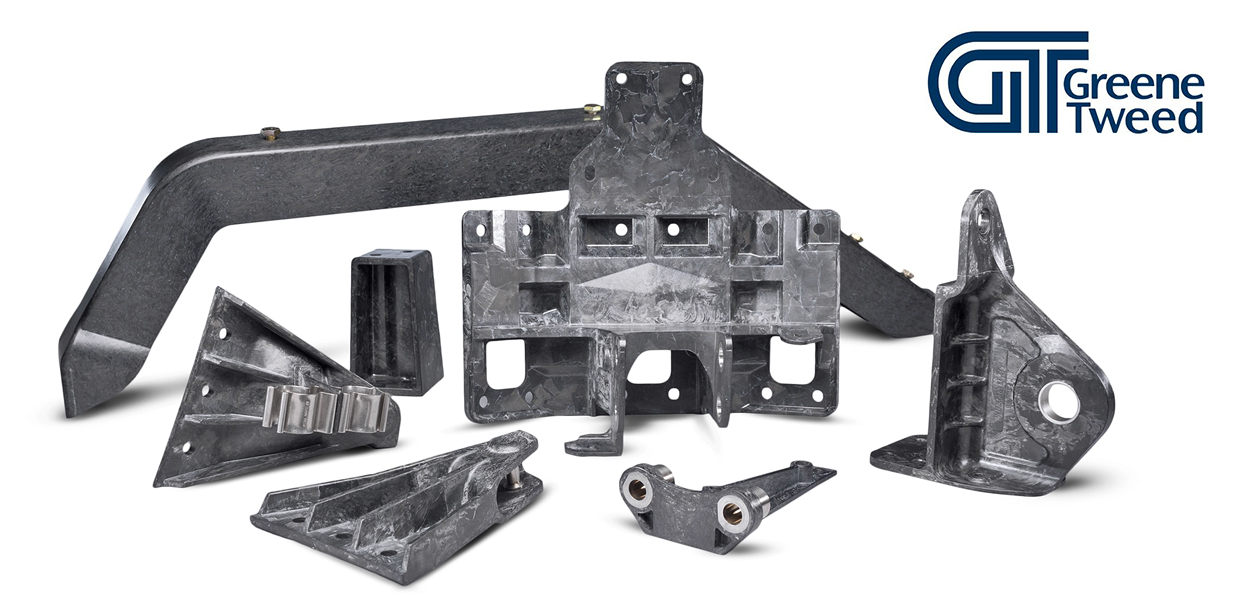

Under the agreement, Greene Tweed

will supply more than 50 custom-designed parts using its proprietary Xycomp

DLF material, a compression-molded thermoplastic composite engineered to

be up to 60% lighter than traditional metals, while delivering the

strength and durability required for critical aerospace use. These components,

including complex engine bracketry and aerodynamic fairings, directly support

improved fuel efficiency, reduced emissions, and enhanced engine performance, key

drivers for sustainable aviation.

By replacing heavier metal

components with lightweight thermoplastics like Xycomp DLF , we are helping

create more efficient, sustainable, and high-performing jet engines without

sacrificing reliability, said Magen Buterbaugh, President and CEO of Greene

Tweed.

Key Advantages of Xycomp

DLF :

- Weight Savings: Up to 60% lighter than metal

alternatives

- Durability: Meets stringent aerospace

performance requirements

- Sustainability: Supports lower fuel

consumption and emissions

With a legacy of powering over 80%

of the world s aircraft with high-performing materials, Greene Tweed

continues to leverage its technical expertise, precision manufacturing, and

sustainability commitment to deliver tailored aerospace solutions at scale.

Source: www.gtweed.com