Fives Group Advances Aerospace Composites Automation with Smart Factory and Inspection Innovations

BY Composights

Published: 26 Aug 2025

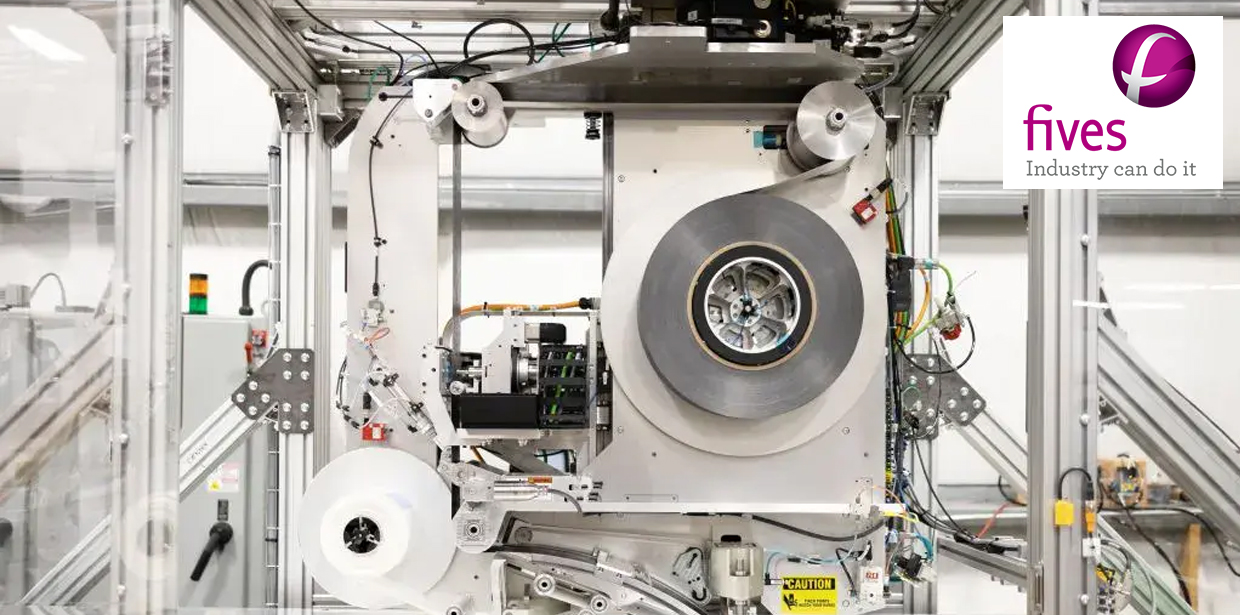

Fives Group, a global leader in advanced

manufacturing systems, is reinforcing its position at the forefront of aerospace

composites automation with new breakthroughs in automated fibre placement

(AFP), automated tape laying (ATL), and in-process inspection technologies.

With over 200 fibre/tape systems installed worldwide, the company s

Cincinnati and Lund divisions continue to shape the future of composites

manufacturing for both civil and military aircraft, as well as space vehicles.

Fives flagship Cincinnati SuperCharger ATL system

delivers higher deposition rates, on-the-fly cutting, and integrated scrap

management, while the Robotic Viper AFP platform provides a

cost-efficient solution for automating hand layup processes without

compromising quality. Both machines integrate seamlessly with Fives ACES

(Advanced Composites Environment Suite) simulation software, enabling users

to optimise material utilisation, prevent head collisions, and validate part

designs in a virtual environment.

The group has also introduced COAST (Composite Optical

Automated Surface Tracking), its in-process inspection system that reduces

cycle times by up to 28% compared to manual inspection. Looking ahead, Fives is

preparing to deliver patent-protected measurement systems based on optical

coherence tomography (OCT), enhancing accuracy for complex geometries at

faster speeds.

Automation is central to the future of composites, said

Stephen Albers, Fives composites expert. From the B-2 bomber to

next-generation single-aisle aircraft, automation enables speed, quality, and

material savings that manual methods cannot achieve.

Beyond machinery, Fives is embracing Smart Factory

philosophies and digital twin technologies, allowing aerospace

manufacturers to connect design, simulation, production, and inspection in a

unified digital ecosystem. This integration supports the push for higher

production rates demanded by OEMs, particularly for next-generation

single-aisle programs.

Fives is excited to be an end-to-end provider in

composites, added Justin Falck, marketing and communications manager.

From software and simulation to equipment and inspection, we provide a

complete solution to help our partners reduce waste, improve efficiency, and

meet the demands of a booming aerospace market.

Source: www.fivesgroup.com