First Wind Park Applies We4Ce and CNC Onsite New Technology for Blade Root Composite Repair Technique

BY Composights

Published: 10 Jul 2025

Danish precision machining specialist CNC Onsite and Dutch rotor blade expert We4Ce have successfully completed their first joint project,

bringing advanced blade repair expertise to a wind park in South Asia. In May,

the companies trained the customer s technicians to independently repair loose

blade root bushings on 26 turbines, marking the first in-field application of

their new remanufacturing method. This innovative approach utilizes a custom

machine, designed and built by CNC

Onsite, to drill out defective bushings from the rotor blades composite

laminate, creating precisely dimensioned holes for replacements. By leveraging composite materials and

on-site repair techniques, the method offers a cost-effective, sustainable

alternative to full blade replacement, eliminating the need for offsite

transport and significantly reducing blade waste.

CNC Onsite s custom-built precision machine removed the

damaged bushings on-site, enabling the park s technicians to apply We4Ce s

patented Re-FIT bushing and fastening method. Ahead of the 50MW project, the technicians were

trained at We4Ce s laboratory in the Netherlands on the repair technology, and

at CNC Onsite in Denmark on operating the precision machine. Delivered under a

licensing model, this technology transfer enables wind parks to carry out major

blade repairs using their own service teams. Following their training, the

South Asian service team set up a field workshop at the wind park and, under

the supervision of CNC Onsite and We4Ce, carried out large-scale repairs over

several weeks.

Securing and completing this first contract for our bushing

and insertion method is the result of fine engineering for practical

application, says Arnold Timmer,

managing director of We4Ce. We first conceived the idea in early 2022 after an

initial job with a client in India and then spent three years developing and

testing the solution.

By adopting the remanufacturing technology, the

customer will restore more than 1,000 bushings. The process combines precision

milling, a specialized fixing method, and the installation of replacement

bushings to produce a like-new component engineered for reliable performance

over a lifespan of up to 20 years. This approach represents a significant

improvement over conventional repair method.

Remanufacturing Technology: A Future Option for O&M

With operation and maintenance (O&M) crucial

to long-term turbine performance, remanufacturing, restoring parts to equal of

higher quality than original condition, is likely to shape how the wind sector

approaches maintenance in the years ahead.

Replacing bushings as an aftersales activity is a complex

process, requiring precise removal and re-insertion for a strong mechanical

bond.

Three industrial work tents, each measuring 100 m and

housing a rotor blade, were set up as clean environments. In the first tent,

one blade was drilled; in the second, the bushing replacement was carried out;

and in the third, final flattening was completed.

The We4Ce and CNC Onsite method provides significant

advantages: up to 60 percent in cost savings, reduced downtime, and

environmental benefits from eliminating potential blade waste and blade

transportation, which would typically incur high logistical costs and CO2

emissions.

Efficient Drilling in Fiberglass Blades

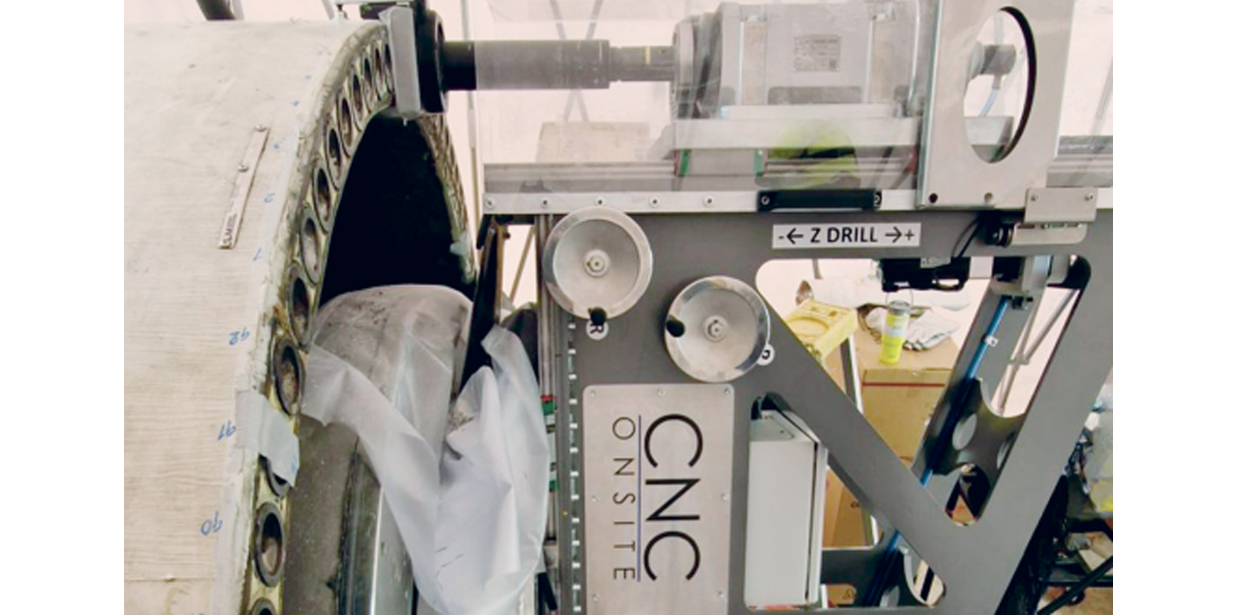

CNC Onsite designed and built a custom machine to drill out

defective bushings from the rotor blades composite laminate, creating

accurately dimensioned holes for replacements.

Drilling in fiberglass is typically hard on the tools causing them to wear out quickly. That is why as part of this project, we developed special drills to achieve high precision and efficiency, explains Soren Kellenberger, partner and sales director, CNC Onsite.

We4Ce applied its patented infusion technology to fasten the new replacement bushing in place, ensuring exact centering. Epoxy resin was infused through an inlet tube into the base of the bushing, with vacuum processing ensuring even distribution around the cavity.

The blade root bushing, or insert, is a safety-critical component that connects the rotor blade to the turbine hub. In some blades, polyester is used to embed the bushing. If during the original manufacturing process this material shrinks or is unevenly distributed, microcracks can arise with cracks developing over time. Such cracks reduce the bonding surface and increase the risk of the bushing loosening, potentially leading to blade failure.

We4Ce and CNC Onsite are currently preparing for upcoming projects with significant potential, including Brazil and the US.