DLR Study Confirms Polyamide 6 as Viable Low-Cost Tooling Option for AFP Composites

BY Composights

Published: 28 Jul 2025

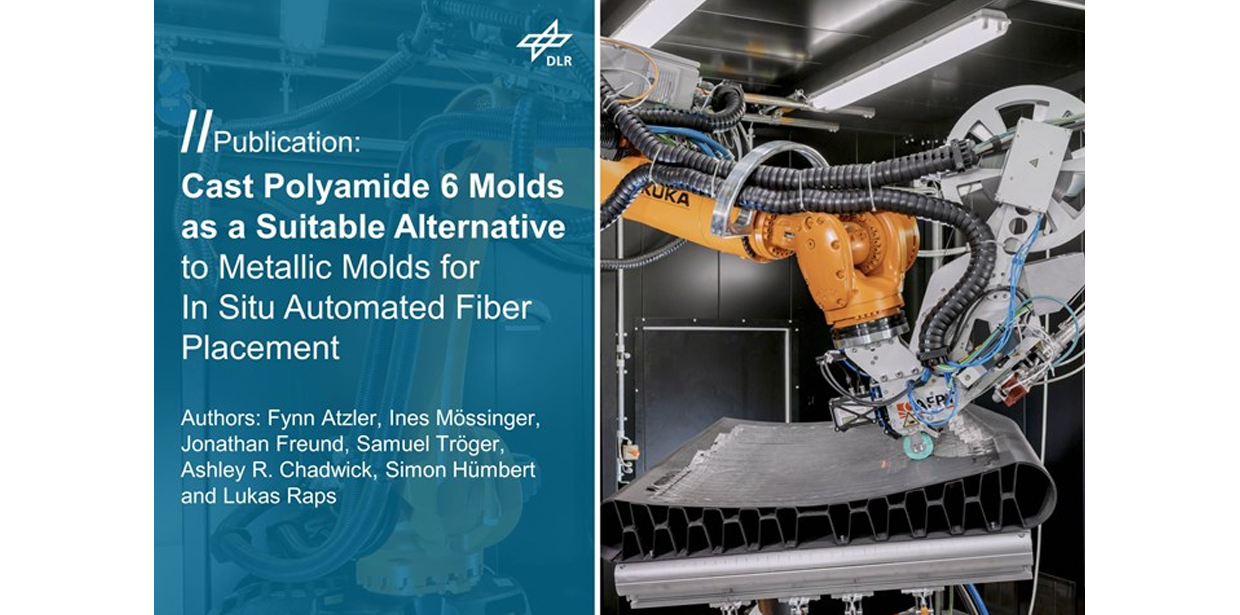

The German Aerospace Center (DLR) has released a new research

paper validating the use of polyamide 6 (PA6) thermoplastic molds as a cost-effective

alternative to traditional metal tooling in the in situ automated fiber

placement (AFP) process.

With growing interest in 3D printed composite tooling for faster,

more affordable production, DLR compared the mechanical and morphological

characteristics of carbon fiber-reinforced LMPAEK laminates produced on

both metallic and PA6-based molds. Evaluations included tensile

strength, interlaminar shear strength, and detailed analysis via scanning

electron microscopy (SEM) and differential scanning calorimetry (DSC).

Despite inherent material differences in stiffness and thermal

conductivity, the study found no statistically significant differences

in the mechanical or crystalline properties of the laminates, affirming the

performance of PA6 tooling in nonheated AFP environments.

These findings demonstrate that PA6 molds offer a viable, low-cost

alternative to conventional tooling, especially for non-heated

applications, stated DLR researchers. We now plan to extend this work to our 3D

printing efforts, unlocking greater flexibility and efficiency in

composites manufacturing.

This breakthrough highlights the potential of polymer-based tools for rapid

prototyping, short production runs, and lightweight tooling

applications, contributing to more sustainable and agile aerospace manufacturing

workflows.

Source: www.dlr.de/en