Continuous Composites Awarded $1.9M U.S. Air Force Contract to Advance FEA for CF3D

BY Composights

Published: 25 Aug 2025

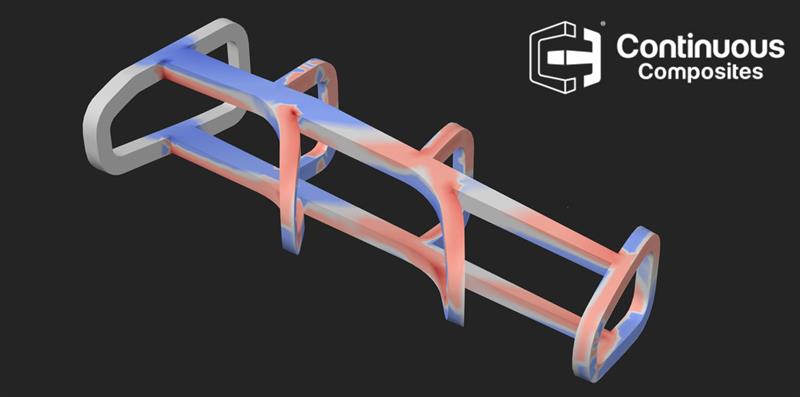

Continuous Composites (CCI)

has secured a $1.9 million Tactical Funding Increase (TACFI) contract

from the U.S. Air Force to develop a next-generation Finite Element

Analysis (FEA) tool for Continuous Fiber 3D Printing (CF3D). The

program, launched in November 2024 and running through August 2026,

aims to revolutionize the simulation of anisotropic composite materials,

which display directional strength based on fiber orientation.

Traditional FEA solutions

primarily model isotropic materials such as metals, where stress responses are

uniform. However, CF3D composites are anisotropic, requiring simulation tools

that account for fiber steering and direction-dependent properties.

We re solving a major gap in

FEA simulation tools, said Steve Starner, CEO of Continuous Composites.

Existing platforms oversimplify composite behavior, but our new solution will

dynamically simulate fiber orientation and structural response, which is

critical for aerospace and defense applications.

The new tool will directly ingest

CF3D toolpath data to create mesh representations that more accurately

reflect real-world performance. Integration into CF3D Studio will

enable engineers to predict material properties and part performance before

physical testing, reducing development cycles and improving design reliability

for mission-critical parts.

This milestone represents a major

step in evolving CF3D from a manufacturing process to a full design-to-performance

ecosystem, supporting applications in aerospace, defense, and UAV

sectors.

Source: continuouscomposites.com