REFRESH Project Advances Sustainable Wind Blade Disposal

BY Composights

Published: 25 Sep 2025

In a groundbreaking

development, the EU-funded REFRESH project has shown promising findings

from its first life cycle assessment (LCA)

on recycling glass fibre and carbon

fibre reinforced composites from end-of-life (EoL) wind turbine blades.

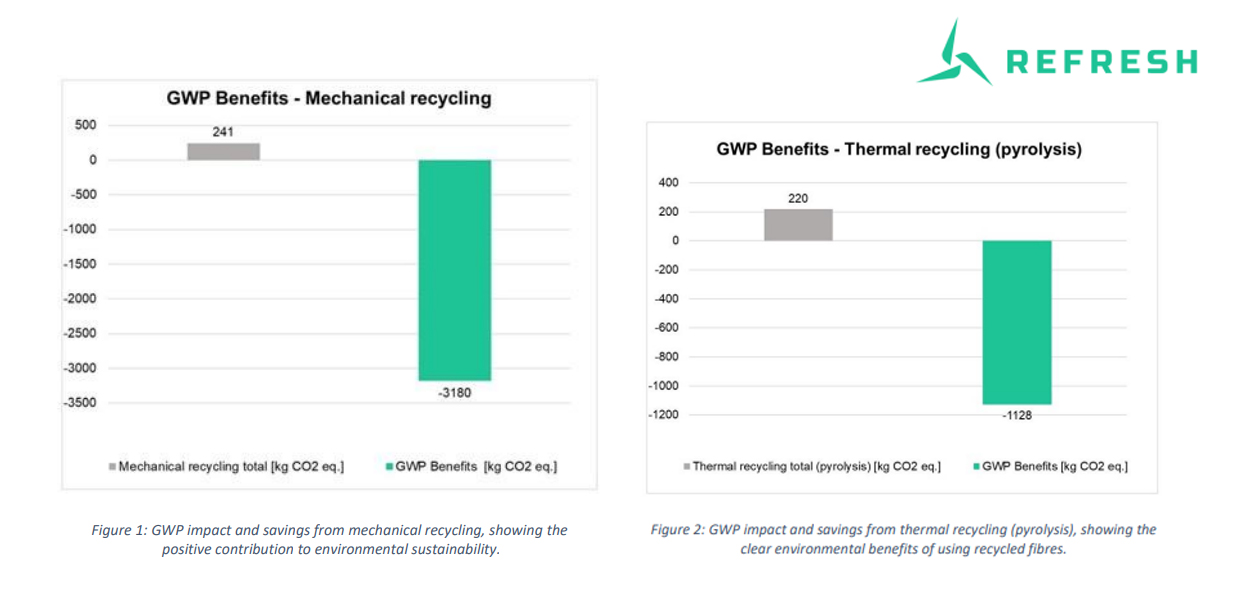

The study shows that both mechanical and thermal recycling processes deliver

significant environmental gains over conventional disposal methods.

Notably,

thermal recycling demonstrated more than a 70%

reduction in climate change impacts compared to incineration, positioning REFRESH as a game-changer in

sustainable composite waste management. The evaluation of advanced recycling

techniques, including microwave-assisted pyrolysis, remain underexplored in

existing environmental assessments.

The evaluation of advanced recycling techniques, including microwave-assisted pyrolysis, remain underexplored in existing environmental assessments. This study, based on high-quality primary and experimental data sourced from the project s partners, provides a comprehensive and data-driven assessment of innovative recycling processes for composites derived from EoL blades, a topic of increasing importance in the transition to a circular economy. The study included a detailed hotspot analysis, providing actionable insights for reducing environmental impacts across different process phases.

REFRESH Environmental Impact Assessment

Conducted by RINA Consulting, in the initial phase of the project, the analysis followed the ISO 14040 and 14044 standards. The functional unit for the analysis was defined as the recycling of 1 ton of EoL wind turbine blades.

The

analysis covers the project s three main recycling processes: mechanical

recycling, and two thermal processes pyrolysis, and microwave-assisted

pyrolysis (MW-pyrolysis).

The

comprehensive LCA provided a thorough evaluation of the environmental impacts

across the entire lifespan of the recycling processes. The calculations were

performed using the GaBi LCA for Expert software. The study focused on three

main impact categories:

- Climate change;

- Resource use (fossils); and

- Resource use (minerals and

metals).

The characterisation method used was the Environmental Footprint (EF)

3.1 method, which is aligned with the latest standards and EU recommendations.

Comparison with Linear Disposal Scenarios

Mechanical

recycling demonstrated a 2% reduction in

environmental impact compared to landfilling. Despite the relatively low

percentage reduction, it is important to highlight the generation of secondary

raw materials through the recycling process.

The thermal recycling processes, pyrolysis and microwave-assisted pyrolysis, demonstrated a remarkable 71% and 72% reduction in climate change impact, respectively, compared to incineration. This highlights the potential of these processes for significantly reducing greenhouse gas emissions.

All three recycling processes demonstrate significant environmental benefits compared to the impact of the recycling process itself. Figures 1, 2 and 3 show the global warming potential (GWP) benefits offered by the mechanical recycling and thermal recycling processes.

Next Steps

This initial LCA analysis indicates that the REFRESH recycling processes have the potential to significantly reduce environmental impacts compared to traditional disposal methods. The substantial environmental benefits of using recycled materials further support the project s goals of promoting circular economy practices and reducing reliance on virgin materials.

The next steps involve optimising the processes, assessing the final use of the recycled materials, and conducting an economic and social assessment to maximise the project s sustainability potential.

Source - refresh-project.eu