3. How SpiralRTC Recycles Thermoplastic Composites

Image 2: Spiral RTC's production site

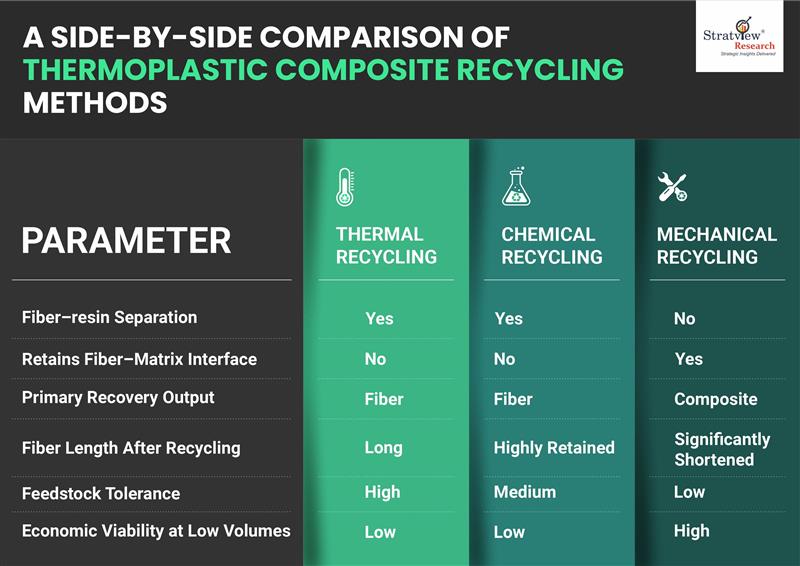

Thermoplastic composites can be recycled in several ways, including thermal and chemical methods that separate the polymers and fibers. These methods break down the material. However, Spiral RTC uses a different approach: mechanical recycling that keeps the whole composite intact.

Image 3: Side-by-side comparison of thermal, chemical, and mechanical thermoplastic composite recycling methods

Luinge explains, The inherent potential of thermoplastic composites is that we fully reuse materials. So we don t separate the fibers from the resin. We have an efficient process, which is mechanical recycling, to reuse the full material without separation. In principle, it's an energy-efficient process, and the advantage is that you maintain more of the inherent value of the material. This principle defines SpiralRTC s process: preserving the fibre-matrix combination and reusing it as a composite, rather than breaking it down into its constituents.

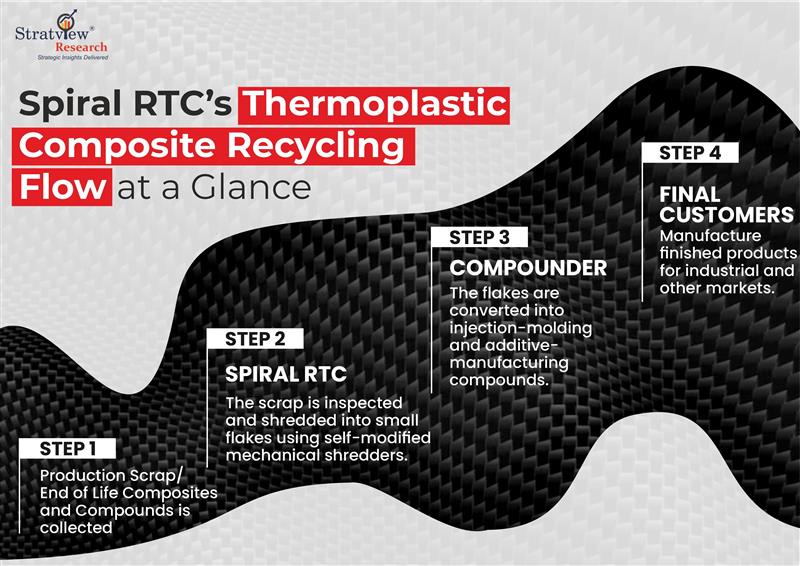

Image 4: Overview of Spiral RTC's thermoplastic composite recycling flow, showing material collection, shredding into flakes, compounding into usable materials, and supply to final customers for manufacturing applications.

Where the Material Comes From

SpiralRTC's input material mostly comes from production scrap, which is sourced directly from manufacturing environments. As Luinge explains, "Currently it's mostly production scrap, well-controlled materials from different industries, from aerospace, industrial, from consumer applications." The company also uses end-of-life material, but production scrap is the main focus due to its consistent and known composition. "This technology is inherently suited to convert these waste streams into new products", he adds.

Source Separation and Inspection

How material is handled before it reaches SpiralRTC is crucial. Thermoplastic composites, unlike unreinforced plastics, cannot be reliably sorted later on, making source separation essential. As Winand Kok explains, It s very important that these materials are separated at the source, or that they are clean, so we can really use the material as one single material.

In conventional plastic recycling, mixed material streams can often be corrected after collection using downstream identification and separation steps. This is not the case with carbon-fibre-reinforced composites. Those detection systems do not work for materials that are highly filled with carbon fiber, Kok says. The carbon fiber itself prevents the system from working. As a result, SpiralRTC relies on receiving clean, sorted material from the start, rather than depending on downstream sorting to fix mixed inputs.

Even then, incoming waste is inspected before processing begins. Contamination is assessed carefully, because while some can be tolerated, some contaminations can really ruin a batch of material, Kok notes. Inspection, therefore, acts as a necessary control step before mechanical processing starts.

Mechanical Shredding

After inspection, the material is reduced in size using mechanical means. This step is simple in theory, but difficult to do in reality because reinforced thermoplastics are very abrasive. As Winand Kok explains, Then we use mechanical shredders, modified by us because these materials are abrasive. Once reduced to smaller pieces, the shredded material is prepared for the next stage. We shred to smaller pieces, then send it to a partner compounder, Kok says.

Image 5: Regrind intermediate material produced after mechanical shredding of thermoplastic composite scrap by Spiral RTC.

Compounding into Usable Materials

Compounding is done by external partners who use standard industrial equipment. Winand Kok explains, They feed it into standard compounding equipment to make injection molding compounds. At the same time, SpiralRTC is also working on recycled composite materials for additive manufacturing. As Hans Luinge notes, These compounds are also used for additive manufacturing. The materials that result from this process are considered new, ready-to-use thermoplastic composite compounds.

Image 6: Injection moulding and additive manufacturing recyclate after compounding recycled thermoplastic composite regrind.

4. Where Recycled Thermoplastic Composites Are Being Used Today

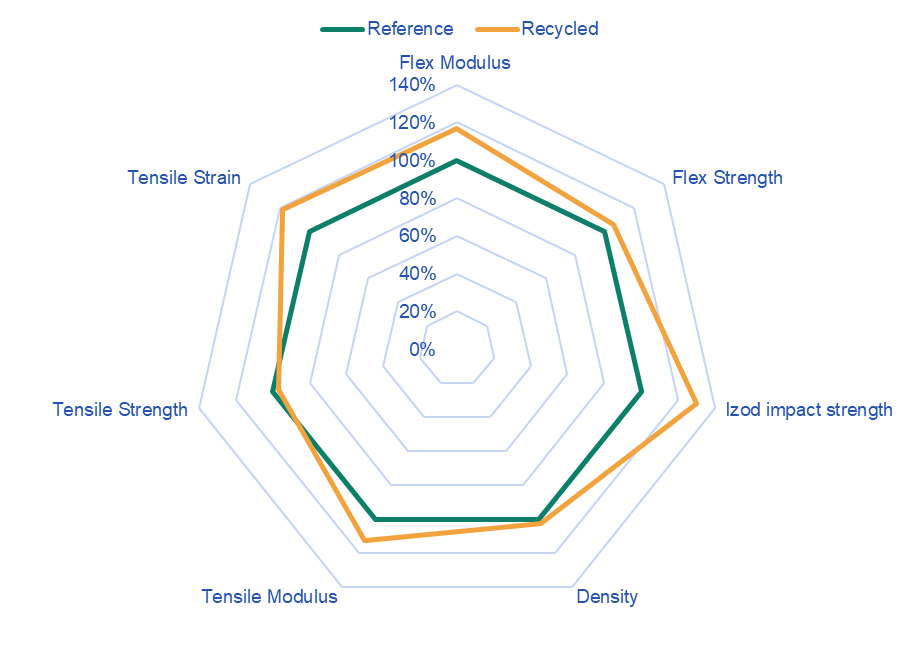

A key question about recycled composites is whether they lose performance when recycled, which affects where they can be used. When Spiral RTC's recycled thermoplastic composite is compared to a virgin industry standard reference material, the results show that it keeps most of its core properties, such as tensile strength, tensile strain, density, and flexural strength. This means the recycled material is not just for low-value uses, but can also meet the needs of load-bearing parts.

Image 7: Mechanical Performance Comparison of Recycled Thermoplastic Composite vs. Virgin Industry Reference Material

As a result, these recycled thermoplastic composites are already being used in real-world applications. They are currently most popular in industrial markets, where recycled compounds are used to make injection-moulded machine parts, including wear parts that need to be replaced often and can be recycled again, helping to create a circular flow of materials.

Image 8: Injection-moulded water pump housing weighing approximately 10 kg, produced using recycled thermoplastic composite material supplied by Spiral RTC.

Another area where they are being used is additive manufacturing, where highly filled recycled composites are used to make 3D-printed tooling and molds for prototypes and small production runs. These tools can be recycled mechanically after use, creating a fast and repeatable cycle.

5. Looking Ahead

With the thermoplastic composites market projected to reach USD 30+ billion by 2040 (according to Composights), the absence of a robust recycling ecosystem will surely put pressure on the sustainability narrative of the thermoplastic composites. In this context, Spiral RTC stands out clearly as a proactive initiative trying to make thermoplastic composites truly circular. By laying stress on the coordination and execution of the already established technology, and functioning independently between waste generators and downstream users, the company is addressing gaps that had limited recycling to theoretical discussions.

The applications discussed earlier show that recycled thermoplastic composites are already being utilised in real-world projects, highlighting the practicality of this approach. Whether this model, or similar initiatives focused on overcoming the discussed challenges in TPC manufacturing, gains wider acceptability across the industry will ultimately influence how effectively thermoplastic composites can achieve their long-promised circular potential.